Last updated on June 25, 2024.

Plastic toys are hot-ticket items during the holiday season. When shoppers are considering their purchases, safety and quality can play a role when deciding what to buy. Plastic toy manufacturers verify the quality of their products on the production line through spot checks and batch testing. The toys are also thoroughly inspected to ensure that they comply with international safety standards.

We’ve talked in the past about how XRF instruments can play a role in making toys safe, but did you know that some of our other instruments are used to help control toy quality? Toy manufacturers use instruments such as ultrasonic thickness gauges to verify the wall thickness and uniformity of injection molded toys, which is an essential aspect of their overall quality and functionality.

A Look at Plastic Materials: The Building Blocks of Toys

Plastic is one of the most common materials used to make modern toys. Plastic is such a popular manufacturing material because it’s durable—it can usually be bent and twisted without any serious damage. Plastic is also versatile. It can be molded and used in many ways to create a huge variety of toys. Toys made from plastic also have some advantages. They last a long time, can stand up to the rigors of play, and are easy to clean. |

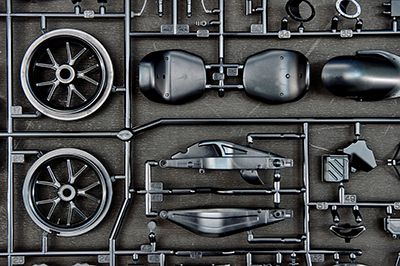

Pieces of an injected molded toy—some assembly required |

How Plastic Toys Are Made—The Thick and Thin of Injection Molding

The manufacturing process of certain toys—for example, building blocks and dress-up dolls—involves a technique called injection molding. Different types of plastic materials are injected in granular form into a precisely designed mold. The plastic is heated so it melts to a paste and lines the mold, and then it is cooled so it hardens. In the case of dolls, rotational casting (or roto-molding) is sometimes used to ensure that the plastic walls of the toys are uniform. Essentially, the mold is rotated slowly while heat is applied so the paste spreads evenly. |

The raw plastic pellets used in injection molding |

Manufacturing High-Quality Toys: More than Just Child’s Play

Precision for the wall thickness of these parts is critical. If the dimensions exceed the established limits, flaws and damage can occur.

Too thick:

- The toy may not work according to the design specifications

- It’s more expensive to manufacture (wasted raw material)

- The toy can warp; thinner walls are actually less prone to warping

Too thin:

- The part is less durable and won’t stand up as well to the rigors of playtime

- It’s more expensive to produce as thinner parts require exponentially more pressure to inject the plastic paste, which wears out the mold faster

A toy’s wall thickness needs to comply with the tolerances set out in the design specs. For injection molded parts that are 1 to 20 mm thick, tolerances are as little as ±0.1 mm. Getting an accurate measurement on walls this thin was very challenging using older methods, such as cutting a sample part in half with a utility knife and measuring the thickness with a set of calipers.

How Thickness Gauges Assist the Quality Assurance of Toys

Toy manufacturers can use an ultrasonic or a Hall-effect thickness gauge to perform reliable, on-the-spot quality control. For example, our 39DL PLUS™, 45MG, and Magna-Mike™ 8600 gauges can measure the walls of plastic parts as thin as 0.8 mm (0.03 in.) They can also provide precision measurements of the wall thickness with a standard resolution of 0.01 mm (0.001 in.)

As ultrasonic thickness gauges, the 39DL PLUS and 45MG instruments can make measurements from just one side of the plastic part—no cutting required. Ultrasonic gauges work by measuring the time it takes for an ultrasonic sound wave to travel through the plastic part. The sound wave travels from the transducer through the part until it bounces off the opposite surface to return to the transducer. The gauge measures this transit time and, using the velocity of sound in the material being measured, calculates the thickness.

Hall-effect gauges, such as Magna-Mike 8600 instrument, employ a simple magnetic method to make precision measurements on non-magnetic materials, including plastics. The gauge uses a magnetic probe and a ball on the opposite side of the part to measure the thickness of the plastic wall. Post inspection, wireless capabilities on the 39DL PLUS gauge enable easier sharing, traceability, and reporting of thickness data. With a USB, the Magna-Mike 8600 and 45MG gauges can send thickness data directly to an Excel spreadsheet and other PC programs for quality-control reporting. |

A plastic toy injection molding factory |

Key Takeaways on Quality Checks in Toy Manufacturing

Given plastics’ durability, versatility of manufacturing, and relatively low cost, there’s no doubt that it will remain a popular material for making toys for many years to come. In addition to helping ensure that toys meet quality standards, thickness gauges are also important for making plastic toys as green as possible. Using the minimal amount of material necessary to create a plastic toy is good for the environment, and thickness gauges enable manufacturers to use minimal

resources to create their products. This helps ensure that plastic toys remain on the shelves for many more holidays to come.

Related Content

Through Thick and Thin: Using XRF to Measure Coating Thickness

Did You Know? We Custom Manufacture Probes for Your Specific Applications

Bring the Noise! How Sound Helps Keep Airplanes Safe