Responding to customers’ needs drives innovation. This is evidenced in our global collaboration with UTComp and RPC Technologies to revolutionize nondestructive testing (NDT) of industrial equipment made from fiberglass reinforced plastic (FRP) composites.

The UltraAnalytix® NDT system by UTComp combines a powerful proprietary algorithm with our EPOCH™ 650 ultrasonic flaw detector. The result is a fast, reliable system that can evaluate the strength and condition of FRP composite tanks, pipes, and other critical infrastructure assets. This evaluation is done without the need for destructive testing, operational shutdowns, or hazardous entry into confined spaces.

The UltraAnalytix NDT system is gaining traction worldwide through UTComp’s network of licensees. RPC Technologies, an engineering solutions firm based in New South Wales, Australia, is a licensee and a longtime customer of Evident. The firm has been introducing the system to inspection programs throughout Australia and Asia.

In this post, we highlight how this collaboration is overcoming the challenges of inspecting FRP composites.

What Are FRP Composites?

Lightweight, corrosion resistant, mechanically strong, and versatile, FRP composites are used to make various infrastructure assets—from pipes and ducting systems to process vessels, storage tanks, and ventilation stacks. They are used in a wide range of fields, including oil and gas, chemical processing, pulp and paper, mining, water and wastewater treatment, food processing, and more.

Despite growing acceptance of FRP composites as an alternative to metal alloys and other materials, barriers remain.

The main challenges are awareness and education. When exposed to mechanical and chemical stresses, FRP composites behave completely differently from alloys. Problems usually start in the resin or polymer rather than the fiber reinforcing material. Further, damage is often invisible and undetectable using conventional NDT inspection methods.

There are more than 200 codes and standards covering the construction of tanks, pipes, and other equipment made from FRP composites. Yet, the codes provide no guidance for NDT inspection of FRP assets.

That’s why the UltraAnalytix NDT system is a game changer. The patented system combines ultrasonic data collected in the field using the EPOCH 650 flaw detector and external visual inspection and analysis using UTComp’s proprietary algorithm.

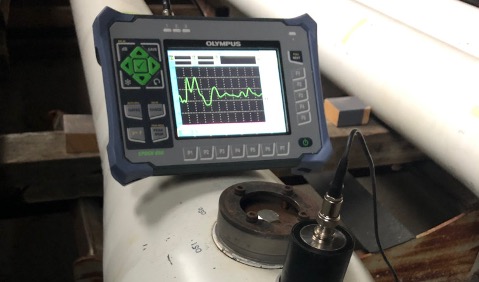

Technicians inspect the reinforcement and attachment of a large nozzle on an in-service FRP storage tank using the EPOCH 650 ultrasonic flaw detector

The UltraAnalytix NDT system accurately calculates values such as FRP thickness, percentage of design stiffness, and remaining service life. As a result, the system provides asset owners with a fast, reliable, and cost-effective method to assess the fitness for service of FRP equipment and predict when the equipment is at risk of failure.

UltraAnalytix results have been validated through academic research and by 500+ comparisons with destructive tests in the field. More than 4,000 assets are now enrolled in UltraAnalytix inspection programs for more than 200 companies worldwide.

Choosing the Right Tool for Accurate Inspection of FRP Composites

UTComp began using EPOCH flaw detectors more than 20 years ago, according to UTComp CEO Jo Anne Watton. As a result, the UTComp team was already familiar with the technology when selecting a potential tool for the system.

“When we were developing our technology, the EPOCH 650 flaw detector allowed us to get data in the way we needed to get it,” said Jo Anne. “We needed the raw data from the backend to enable us to do our analysis for accurate inspection of FRP composites.”

Jo Anne continued, “We were using the flaw detector in a very unconventional way, and Evident deserves a big pat on the back for removing barriers to help us explore innovative ways to use ultrasound to inspect FRP composites. They’ve been cooperative and collaborative in solving problems as they arise while we develop our technology.”

A Growing Collaboration Brings Innovation and Opportunity to the NDT Field

Over the years, the Evident team has provided technical support and software fixes to expand the flaw detector’s ultrasonic inspection capabilities and meet the needs of UTComp and its licensees, Jo Anne said.

“Evident’s relationship with UTComp and RPC Technologies demonstrates our commitment to developing advanced industrial solutions and strengthening relationships with customers in the research and inspection fields,” said Steven R. Berube, the vice president of industrial sales and marketing for NDT at Evident.

Steven noted, “We’ve made a conscious shift to focus on collaborating with customers to solve their challenges. We believe that’s the best way to speed up the development of innovative solutions. These solutions let our customers grow their expertise and create new opportunities in their fields.”

A technician evaluates the condition of an FRP storage tank with a thermoplastic lining (dual laminate) using the EPOCH 650 ultrasonic flaw detector

Today, the EPOCH 650 flaw detector is used by all UltraAnalytix NDT licensees worldwide. RPC Technologies has EPOCH instruments across Australia, including New South Wales, Victoria, and Queensland, as well as Batam, Indonesia, according to Damean Halstead, the UltraAnalytix project and inspections manager at RPC Technologies.

“Our FRP inspection work is mainly focused on industrial chemical tanks for water treatment facilities, such as desalination plants, water filtration, and wastewater treatment plants, as well as mining operations. We have also used UltraAnalytix for R&D work investigating fitness for service of reverse osmosis pressure vessels,” said Damean.

“Evident has always been responsive to our needs. Recently, Evident Industrial Sales Manager Andrew Saliba and Applications Specialist Nick Eleftheriou visited our facility in Newcastle. They were very excited to learn about what we were doing with their ultrasonic flaw detectors,” said Damean. “With UltraAnalytix, we’re pushing the boundaries of how this equipment can be used.”