We recently chatted with Joseph Miller, a consultant to the tin industry, about how X-ray fluorescence (XRF) technology intersects with the mining, secondary production, and scrap industries. Check out the conversation below to learn more about the role XRF plays in the analysis of tin ore, scrap, and bars in various fields.

Q: Joseph, it's great to have you here. You mentioned getting back into the tin industry in 2021. Could you elaborate on your journey since then?

Joseph: Absolutely. After re-entering the tin industry, I transitioned into consulting, primarily focusing on tin both in mining and secondary production. I'm currently a member of the American Tin Association and will be presenting at the International Tin Association's investment conference in London this fall.

Q: As a consultant, what‘s your primary focus?

Joseph: My primary focus is to provide valuable information and expertise to companies in the tin industry, aiding in their decision-making processes and ensuring compliance with industry standards. Whether it's advising on ethical sourcing or conducting due diligence, my aim is to contribute to the sustainable growth of the tin sector.

Q: You have a diverse work background, including military service. How has your previous experience influenced your current work?

Joseph: My military background, particularly in aviation and special forces, instilled in me a sense of precision and adaptability, qualities essential in consulting and navigating complex industries such as mining. Additionally, my involvement in Saudi Arabia's Vision 2030 initiative has provided unique insights into the country's mining sector development.

Q: Could you explain how XRF technology has played a role in your work?

Joseph: XRF technology enables almost instantaneous analysis of the elemental composition in samples. This is particularly useful in both secondary production and primary ore assessment. For instance, in secondary production, XRF analysis helps ascertain the elemental content in tin scrap converted into bars, providing valuable insights into the material's composition and value.

Q: What other tin-based industries are taking advantage of XRF analysis?

Joseph: With its ability to instantly analyze metallic elements in a sample, a handheld XRF analyzer is a must-have for anyone in the mining or scrap industry.

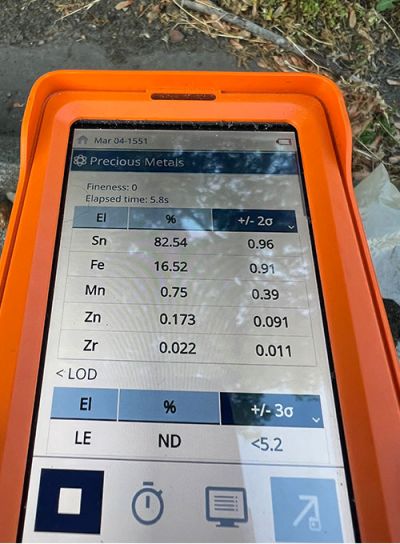

My Vanta Element™ XRF analyzer, made by Evident, is a great example of an XRF 'gun' that can provide accurate readings, as seen from this cast bar made from high-grade tin-bearing scrap. The 21.8 kg bar pictured here was part of a 118 kg cast over the weekend in Virginia. This nondestructive measurement is perfect for field analysis and is commonly used in mines, scrap yards, and prospecting sites.

XRF results of a cast bar made from high-grade tin-bearing scrap. Image courtesy of Joseph Miller.

Q: What are the benefits of handheld XRF analyzers in these industries?

Joseph: A handheld XRF analyzer is easy to use and can upload collective results to a computer. It’s a versatile tool that’s worth the investment. While the initial price for an entry-level analyzer may be steep (around 20k), its quick payoff makes handheld XRF a valuable addition to any operation.

I value XRF because it gives you almost instantaneous ability to ascertain the main elements in any given sample. That works great for secondary production. For example, I had some tin scrap that was converted into bars. The XRF analyzer gives a great analysis of the material in the bars. I usually test each bar in about four different places on the bar because the material isn’t always homogeneous. That gives us a really good idea on the value of the bars. Of course, on the primary ore assessment side, XRF is used in the field to ascertain the quality of tin ore.

|  |

Cassiterite ore sample tested using handheld XRF. Cassiterite is a tin oxide mineral that is the primary source of tin metal. Images courtesy of Joseph Miller.

Q: What elements are you looking for in your work?

Joseph: We’re basically looking at tin oxide. Usually in the pure form it contains around 60 to 70% tin metal. With XRF, you can test a sample, identify the content of the tin, and see if there are other elements involved that are valuable, such as those found in an alluvial placer deposit.

This means technicians can take samples, look at what the material includes, and map out a deposit. I don't have direct experience with it, but XRF is done on the hard rock side where you can't see what you're looking for visually. In the field, this gives you a way to instantly identify if you're on the right path. Ten to 15 years ago, you'd have to take samples, send them off to a lab, and then make sure you kept a catalog of where they were from.

Handheld XRF analyzers enable on-the-spot elemental analysis of samples in the field. Image courtesy of Joseph Miller.

Q: Do you test for rare earth elements with XRF?

Joseph: We may test for tellurium and some other rarer elements. The XRF analyzer gives you a snapshot on what's in the samples you're looking at. In the field, technicians use XRF to sample material, especially on the alluvial side.

Q: How has the Vanta Element XRF analyzer helped in your work?

Joseph: I am very impressed with the Vanta Element analyzer. In particular, I like the ability to check samples, save the data, and download the data with thousands of samples. You can add the exact location of the samples or the piece of material you're looking at, such as whether they are primary or secondary sources of tin. It's a great device.

Q: How do you see XRF technology impacting the future of mining and refining, especially in regions such as the Middle East?

Joseph: Handheld XRF technology facilitates on-the-spot analysis. This aids in sample characterization and resource identification, crucial information for efficient mining and refining operations. In regions such as the Middle East, where there's a push for diversification in mining, XRF technology streamlines the exploration process, contributing to the development of local mineral resources.

Related Content

Plan a Successful Portable XRF Program for Geochemistry: 9 Free Video Tutorials to Get Started

Video: How to Quickly Analyze Scrap Metals Using Handheld XRF