Overview

|

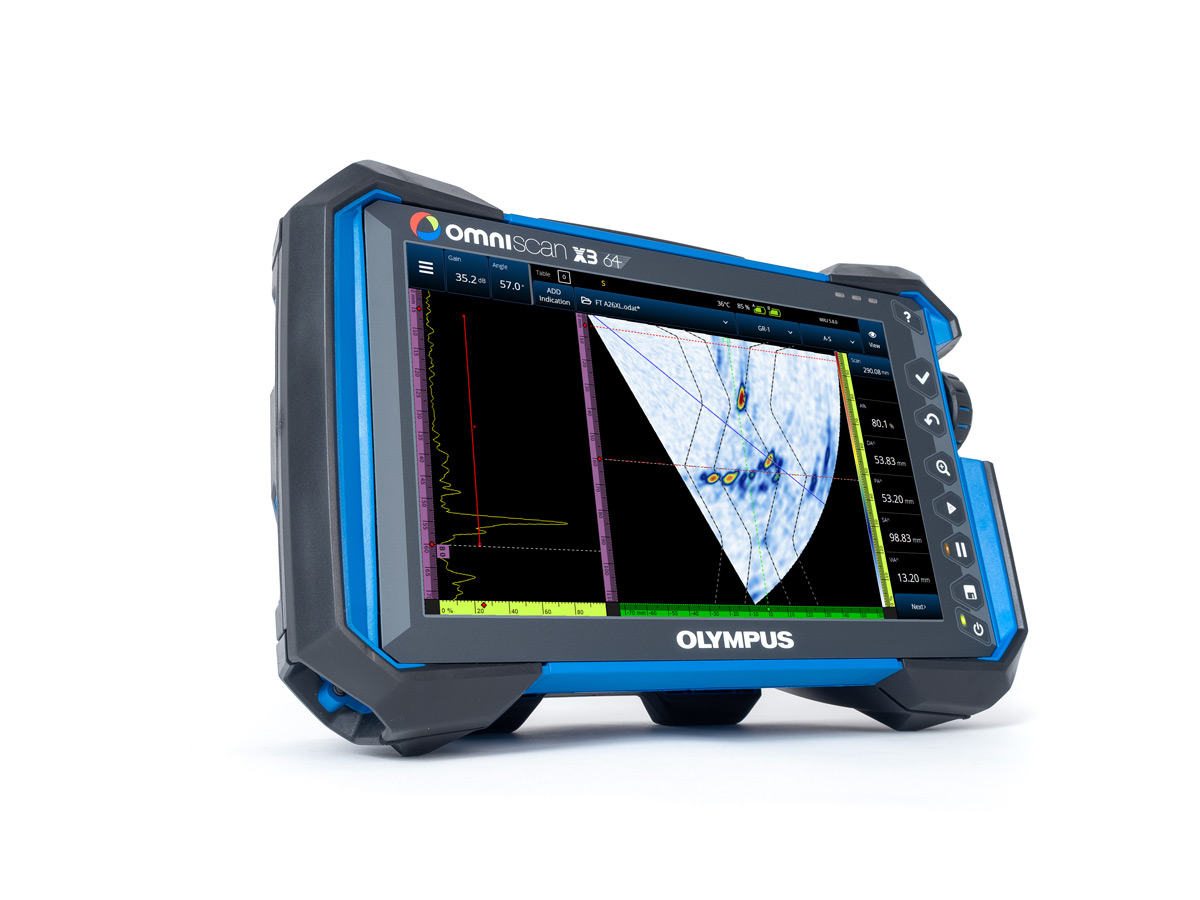

OmniScan™ X3 64 Phased Array and TFM Flaw Detector with Advanced Capabilities

Power You Can Carry

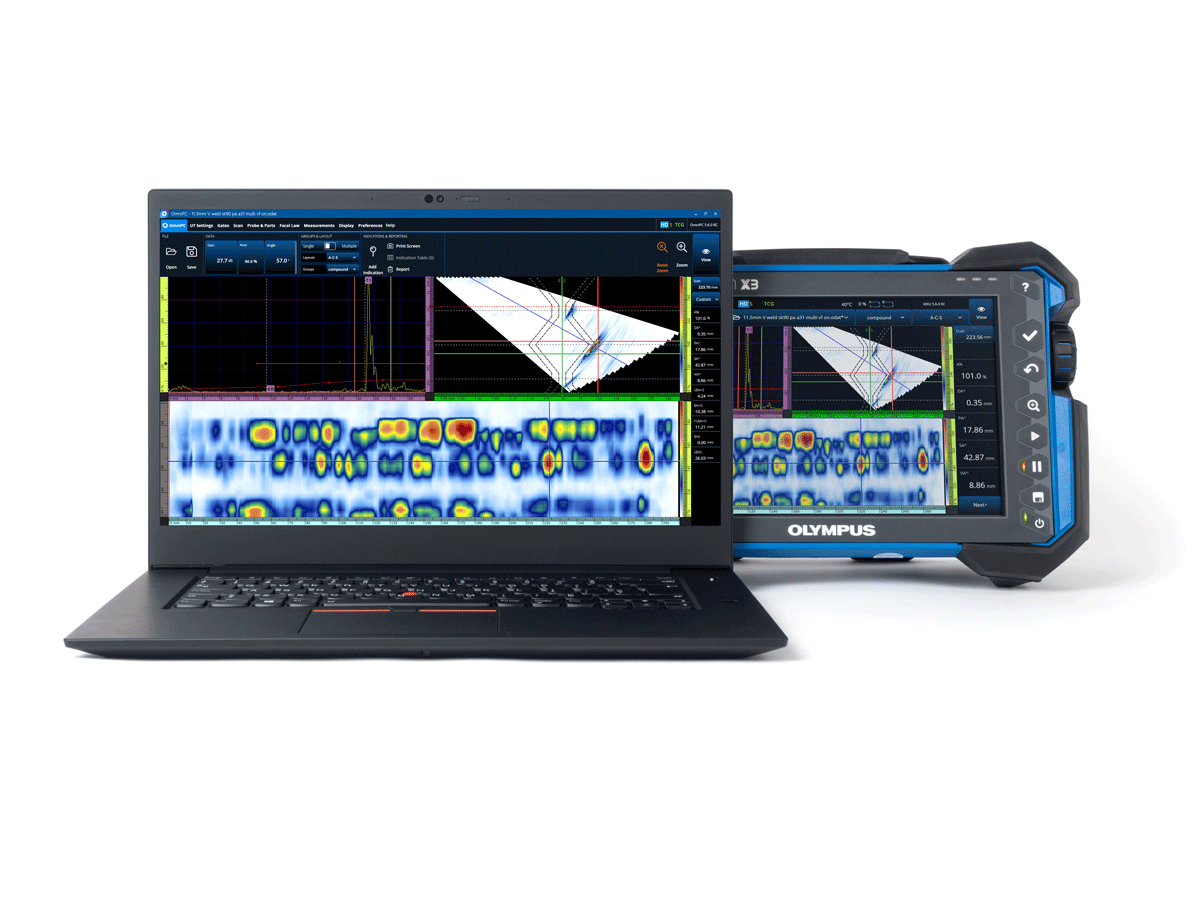

Housed in the field-proven rugged and portable OmniScan X3 enclosure, the OmniScan X3 64 flaw detector’s powerful focusing capabilities supported by its larger element-aperture capacity enable you to fully exploit 64-element phased array probes and 128-element aperture TFM. Utilize its enhanced performance to meet the inspection challenges of thick and attenuative materials and expand your potential to develop new procedures for a wider range of applications. |

|---|

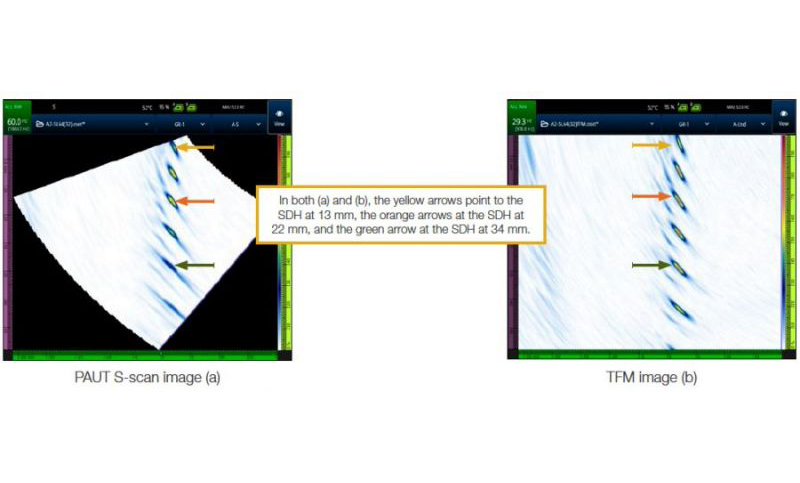

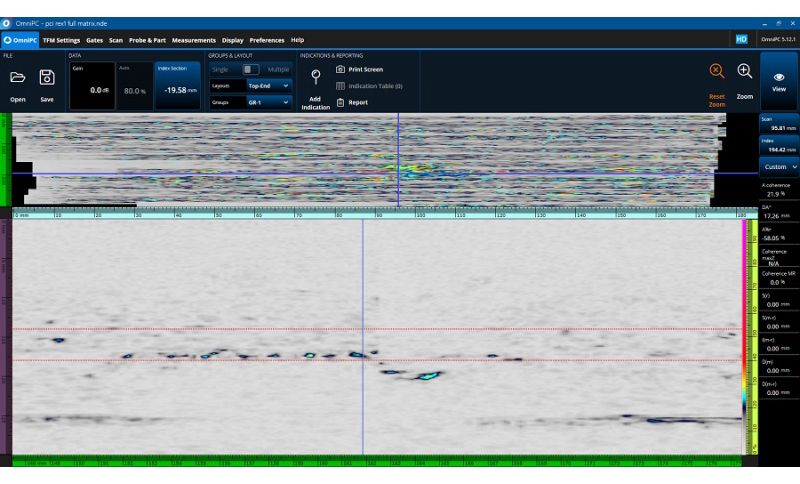

How Our Customers Use the OmniScan Save Time and Energy Screening Welds with the Merged B-ScanIf you’ve ever wondered whether there’s a more efficient way to perform weld screening than simply scrolling through B-scans, you’ll want to hear about our solution. With the MXU 5.13 software update, we introduced an innovative B-scan view for the OmniScan™ X3 series that has the potential to revolutionize this time- and attention-consuming technique. Used as a validation tool, it can give you more confidence in your assessments and help ease the whole B-scan screening process.  5 Main Advantages of Phase Coherence Imaging (PCI)With the release of MXU 5.10 software, the OmniScan™ X3 64 flaw detector gains a new advanced ultrasonic inspection technique: phase coherence imaging (PCI). As soon as your OmniScan X3 64 unit is updated, you can start taking advantage of PCI to achieve live total focusing method (TFM) images with unprecedented clarity and sensitivity to small defects.  Using the Total Focusing Method to Improve Phased Array Ultrasonic ImagingThe nondestructive testing (NDT) industry is experiencing an important technological advancement, as total focusing method (TFM) capable inspection devices are making their entry into the market. The TFM approach represents a significant step forward for phased array ultrasonic testing (PAUT) technology.  Video Probe and UT Technology Assist Cracking Detection in Chrome Carbide OverlayLearn how probe and ultrasonic testing (UT) technology can assist in the detection and characterization of cracking in chrome carbide overlay (CCO). Stephan Couture, global product application leader at Evident, explains and demonstrates techniques to inspect a CCO sample.  FAQs about the Open File Format NDEWith the release of MXU 5.11 onboard software for OmniScan™ X3 and X3 64 flaw detectors, the file format of data files created with these devices has changed from .odat to .nde. This change is the beginning of a shift in how NDT data is managed and accessed. It starts with the OmniScan X3 series but will be applied to all future Evident nondestructive testing software and hardware platforms, and hopefully it will be extended to and used by the entire NDT industry. |

OmniScan™ X3 Phased Array Flaw Detector with Innovative TFM

Confidence You Can See

The OmniScan X3 flaw detector is a complete phased array toolbox. Powerful tools, including total focusing method (TFM) imaging and advanced visualization capabilities, backed by its high image quality enable you to complete your inspection with greater confidence. |

Innovative and Efficient TFM

|

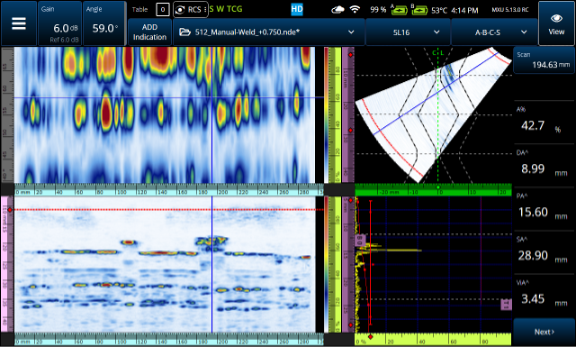

Virtual Collaboration, Virtually AnywhereThe X3 Remote Collaboration Service (X3 RCS) enables you to share your screen, allow a remote collaborator to control the unit, and host a video conference with participants located almost anywhere in the world. Improved, Faster CalibrationThe OmniScan X3 calibrator tracks the signals at high speed. Perform multigroup calibrations in minutes. Familiar Yet Improved OmniScan ExperienceUsers who own or trained on an OmniScan will transition easily to the OmniScan X3 flaw detector, and new users will find it easy to learn. |

Reveal More Details

|

Acquire up to 4X Faster TFMAchieve total focusing method (TFM) acquisition speeds of up to 4 times faster when using a 64-element probe. Compared to models with 32 pulsers, the OmniScan X3 64 flaw detector offers a significant improvement in efficiency owing to its larger aperture capability. |

|

OmniScan X3 Series

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Service and Support You Can TrustFrom calibration to training, we offer a broad portfolio of services to help you maintain optimal device performance. Evident service contracts are:

|

Complete Solutions for Your NDT Workflow

|

Applications

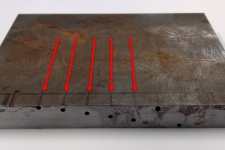

Industrial ScannersThe capacity to accurately position probes according to the surface being inspected greatly influences inspection quality. Olympus offers a wide range of industrial scanners and accessories to assist inspectors in their work. Scanners come in various configurations including one or two encoded axes with manual or motorized motion. |

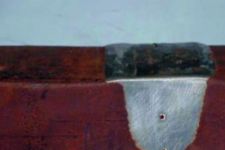

Weld Inspection SolutionsOlympus’ versatile weld solution uses a variety of techniques and scanning tools to achieve a productive and efficient inspection. Phased array, TOFD, and conventional ultrasonic techniques can be used alone or in combination to achieve full-weld coverage with high probability of detection. |

Corrosion Inspection SolutionsOlympus has a wide range of innovative products utilizing advanced technologies for the manual or automated inspections of internally corroded pipes and tanks, high-temperature surfaces, corrosion mapping of large pressurized vessels and stress corrosion cracking are typical applications that require either manual or automated inspections. |

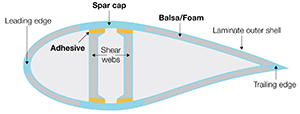

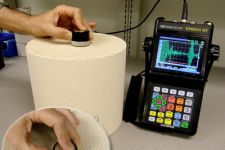

Composite Inspection SolutionsOur composite inspection solutions include portable and integrated inspection instruments that are powerful and fast. Options are available for inspecting several different types of composite and honeycomb parts. Ultrasound and bond testing technologies are packaged with application-specific scanners and probes to address different maintenance or manufacturing industry needs. |

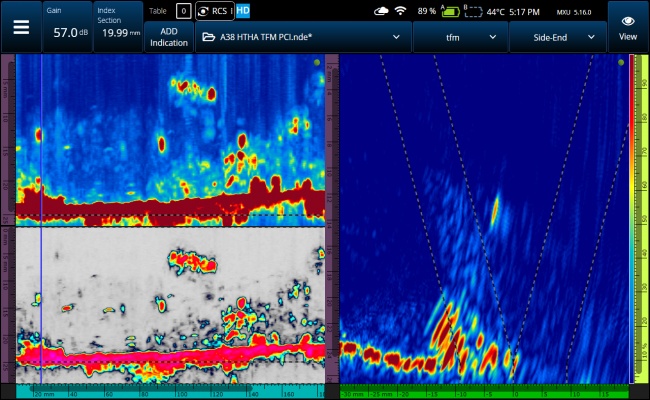

HTHA and Applications Requiring High SensitivityConfidently detect and define complex damage mechanisms such as high-temperature hydrogen attack (HTHA) through the optimal pairing of Evident’s high-sensitivity multielement probes with the advanced imaging capabilities of our data acquisition instruments. These reliable solutions provide clear high-resolution images that increase your probability of detection and enable you to perform precise severity assessments to maintain the integrity of your assets. |

Blog

Uwagi dotyczące aplikacji |

Filmy |

Onboard Software

MXU

PAUT, TOFD, and TFM Inspection and Analysis Software

The OmniScan X3 flaw detector’s MXU onboard software provides streamlined, simplified menus and advanced yet intuitive tools to guide you through your inspection workflow using UT, PA, TOFD, and TFM methods, from setup to reporting. |

Ease Your NDT Workflow Using Built-In Tools | ||

1. Scan PlanFollow the steps—1, 2, 3—to set up your inspection on board 2. CalibrationConduct a fully compliant calibration using the built-in tools | 3. AcquisitionView the live scan results during your inspection 4. AnalysisQuickly and confidently interpret your data |

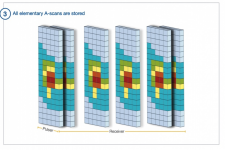

Live TFM Envelope ProcessingFacilitate Flaw Characterization and SizingThe instrument’s unique envelope processing provides high-resolution TFM images. Indications look clean and sharp and stand out more clearly against background noise. Up to four TFM modes facilitate interpretation and sizing. |

Expand Your PA and TFM CapabilitiesIncrease your potential to meet the challenges of your customers and develop new procedures for a wider range of applications. Gain the power to drive advanced PA probes such as our Dual Liner Array™ or Dual Matrix Array™ probes or customized probes to achieve higher quailty imaging of acoustically challenging materials. |

Slide to compare these OmniScan models | When Precision Is ParamountSee Clearly with Lower Frequencies and Wider Bandwidth

|

Fix Errors before They Are Made: Improved PAUT and TOFD Data Quality and ReliabilityThe coupling check channel feature of the OmniScan X3 flaw detector, combined with the ScanDeck™ module’s real-time coupling and scan speed indicators help inspectors monitor data quality before the file is saved.* The coupling quality data is recorded and can be reviewed later. *The ScanDeck module is available on certain scanners, such as the AxSEAM scanner, as of July 2020. |

Avoid Signal Saturation on Large IndicationsEasy Gain Adjustment with 800% Amplitude RangeImprove inspection efficiency by eliminating unnecessary rescanning. The high 800% amplitude range enables you to adjust the gain of large indications, such as lack of fusion, to reference level in post processing, avoiding the need to rescan. |

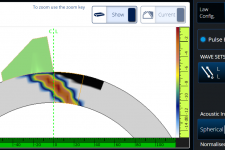

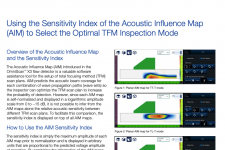

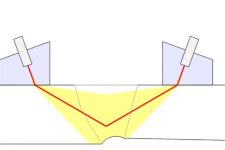

Confirm TFM Beam Coverage in AdvanceThe Acoustic Influence Map (AIM) provides you with an onboard visual model of the sensitivity based on the TFM mode, probe, settings, and simulated reflector. The AIM tool takes the guesswork out of creating your scan plan, enabling you to adjust it accordingly.

|

Complete OmniScan Retrocompatibility for Your ConvenienceReuse your data files from previous versions of OmniPC software and setup files from OmniScan MX2, SX, and MX flaw detectors. To ease your transition, OmniScan .ops setup files are compatible with the OmniScan X3 flaw detector, and .opd data files are compatible with OmniPC 5 and WeldSight software. |

TOFD Lateral Wave ProcessingLateral wave synchronization improves the readability of time-of-flight diffraction (TOFD) data.

|

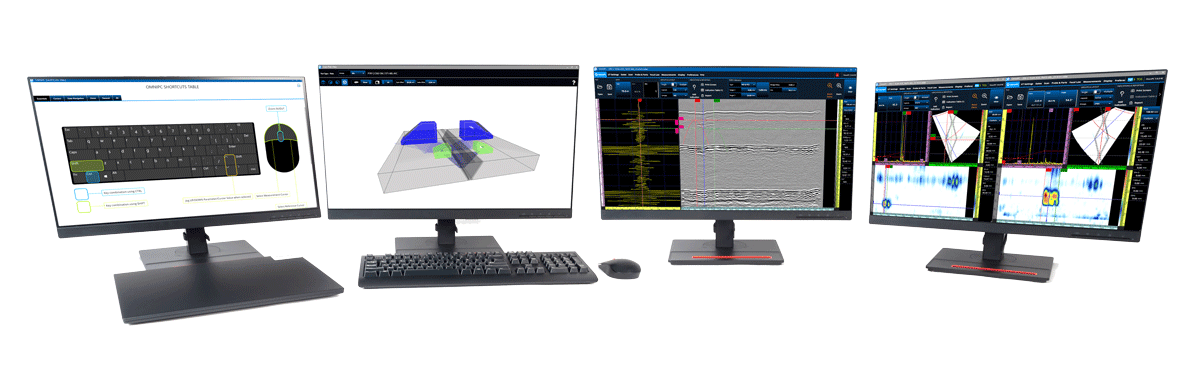

OmniPC 5 Software

OmniPC

Phased Array and Ultrasonic Testing Data Analysis PC Software

OmniPC analysis software is the computer-based companion software for the OmniScan X3 flaw detector. An inspection tool created by inspectors, OmniPC software provides the power and performance to handle all your basic data analysis and reporting needs. |

Why OmniPC?

|

Familiar OmniScan User InterfaceThe user interface of OmniPC software resembles the OmniScan X3 on-board software to ease your learning curve. |  |

Flexible Tools to Ease Your PAUT and TOFD Data AnalysisCorrect Oversights Made during AcquisitionOmniPC software’s Skew, Scan Offset, and Index Offset can be changed during post-inspection analysis to improve data accuracy and avoid reacquisition. Adjustable Gates and Dynamic ReadingsGates A, B, and I are available with various lists of readings (for corrosion inspections). Replay the AcquisitionAt any time, adjust the Gain, apply the Auto 80%, and slide the Data cursors.

| ||||||||||

Specifications

OmniScan® X3 Series SpecificationsThese specifications apply to all OmniScan X3 and OmniScan X3 64 models. • Data Specifications • Acoustic Specifications • TFM/FMC • Operating Environment

Data Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TFM/FMC

Operating Environment

|

Resources

BroszuryPoradnikiInstrukcje obsługi |

WeldSight

WeldSight