Bauxite ore is fine-grained, making identification and quantification of mineralogy onsite or in the field a difficult task. Olympus portable X-ray diffractometers (pXRD) can provide geologists, mining engineers, and metallurgists with quantitative mineralogy in near real-time. Understanding bauxite mineralogy can help optimize exploration efforts, improve

blending strategies, and yield better metal recoveries. XRD is also used by bauxite producers when marketing ore to refineries.

Bauxite ore is fine-grained, making identification and quantification of mineralogy onsite or in the field a difficult task. Olympus portable X-ray diffractometers (pXRD) can provide geologists, mining engineers, and metallurgists with quantitative mineralogy in near real-time. Understanding bauxite mineralogy can help optimize exploration efforts, improve

blending strategies, and yield better metal recoveries. XRD is also used by bauxite producers when marketing ore to refineries.

Benefits of Olympus

The benefits of Olympus' innovative pXRD analyzers include:

- Small sample: requires only 15 mg of material

- Easy sample preparation: does not require a skilled technician

- Fast acquisition time: obtain results in few minutes

- Portability: battery operated, rugged design with no moving parts

- Stand-alone instrument: no need for water cooling or a large, external power source

- No ongoing servicing requirements: XRD can be performed regularly without minimal downtime

Exploration

Bauxite comprises numerous aluminum-bearing minerals (e.g. boehmite, gibbsite, diaspore, kaolin) that exhibit varying degrees of metal recovery. Aluminum that can be recovered during processing is referred to as available alumina. Silica that consumes acid during processing is called reactive silica.

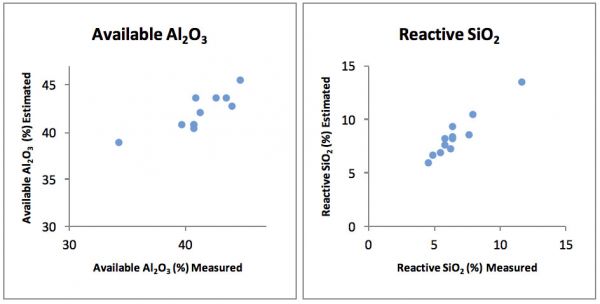

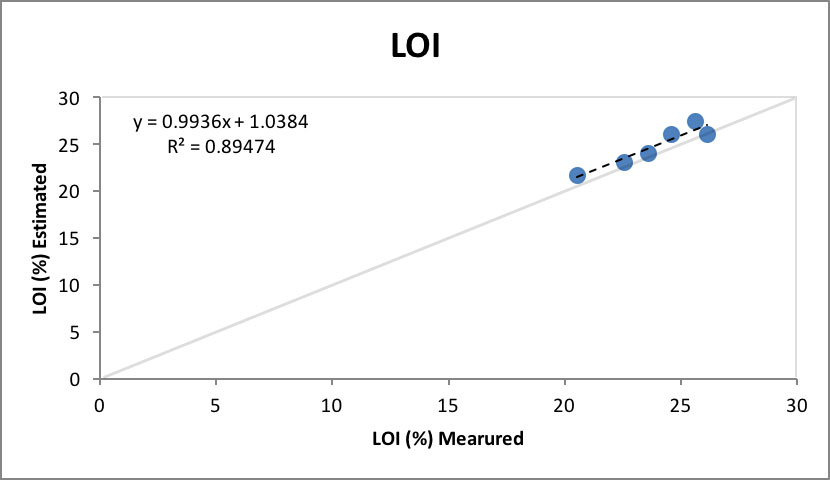

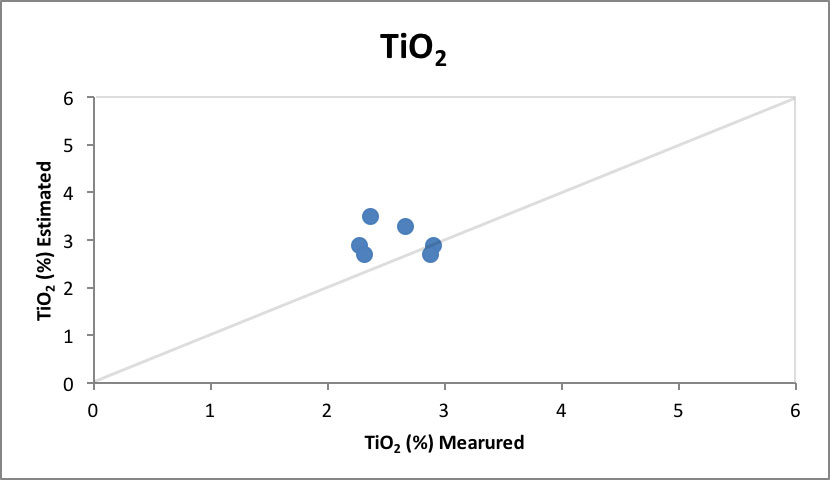

Knowing the amount of available alumina and reactive silica is integral to running an efficient and productive operation. By utilizing an Olympus pXRD instrument, the geologist can quickly determine available alumina and reactive silica in the field to assess the viability of a bauxite deposit (Figure 1).

|

| Figure 1. Excellent correlation between available alumina and reactive silica as measured by a lab compared to estimates from quantitative pXRD. |

Mineral Processing and Extraction

Although important, the bomb digest method (used to determine the amount of available alumina and reactive silica) does not tell you exactly how ore will perform during the refining process. Ore and gangue mineralogy have a large impact on the amount of alumina recovered at the refinery.

Detailed mineralogical modelling and blending strategies can deliver significant project optimization, helping ensure that the best ore product is delivered to the refinery.

Marketing Bauxite Ore

Extraction processes at every refinery are slightly different, so many bauxite producers work to differentiate themselves from competitors. Regular quantitative mineralogical analysis using pXRD can be used as a marketing tool for potential buyers.

Olympus pXRD — Data quality and runtime performance

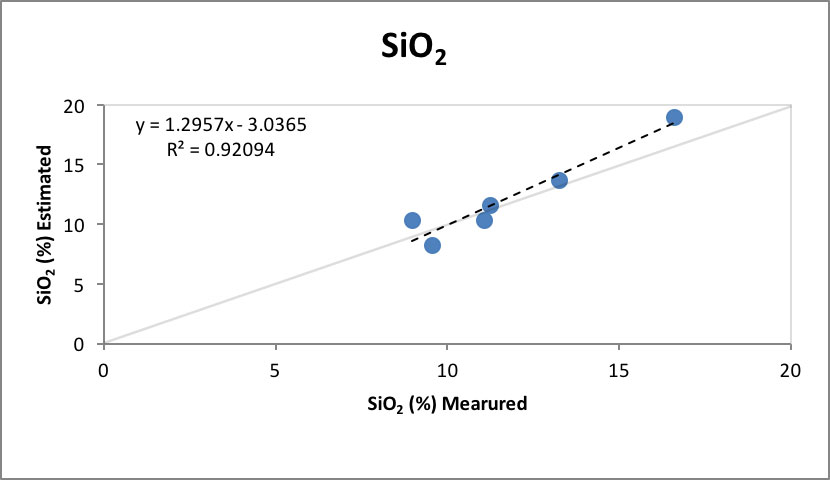

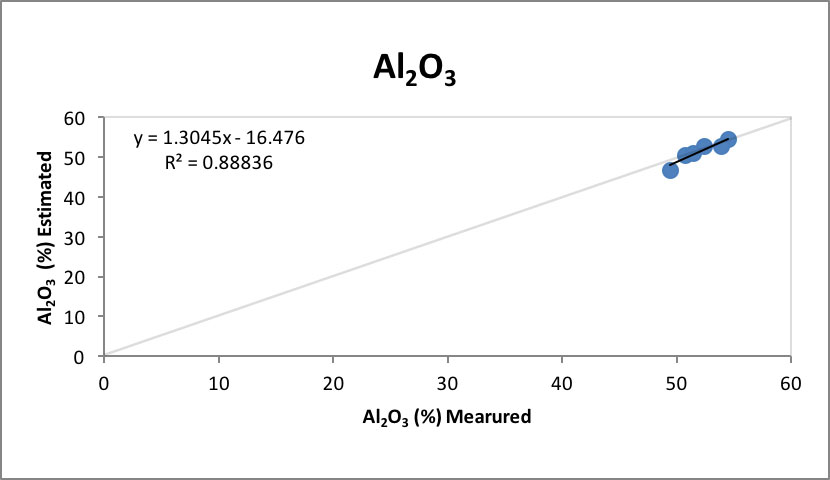

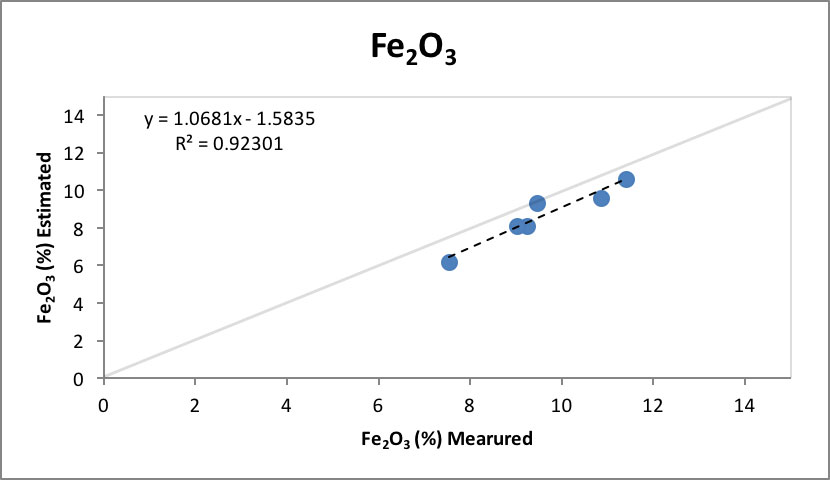

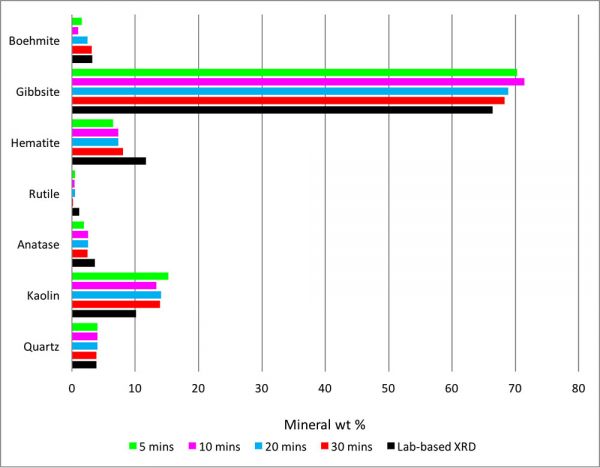

While Olympus pXRD analyzers provide the convenience of quantitative mineralogy onsite, without the need for complicated sample preparation procedures, users can also be confident in the results they obtain. To illustrate the quantitative capabilities of Olympus pXRD analyzers, we compared results obtained using a large, 4 kW, conventional lab-based instrument. Figure 2 and Table 1 (below) illustrate this these results and show excellent agreement between our pXRD instrument and a lab-based instrument.

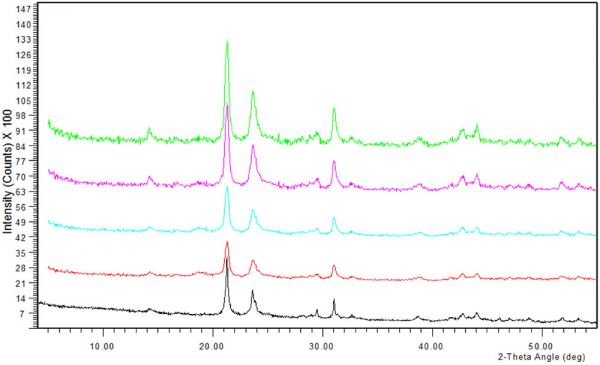

Runtime analysis was also carried out to assess the performance of the Olympus pXRD analyzers at varying runtimes, and this is shown in Figures 3 and 4 below.

|  |

|  |

| |

| Figure 2. Excellent correlation between mineral percentages via XRD from a lab-based, 4 kW XRD instrument and Olympus pXRD with 20 minute runtimes. | |

|

| Figure 3. XRD traces obtained from a lab-based, 4 kW XRD instrument and Olympus pXRD at varying collection times. Please refer to the legend in Figure 4. |

|

| Figure 4. Comparisons between mineral percentages deduced from the XRD traces in Figure 3. Note the excellent relationship between the Olympus pXRD and labbased instrument, even at short runtimes. |

| Mineral | Lab-based XRD | pXRD - 30 mins | pXRD - 20 mins | pXRD - 10 mins | pXRD - 5 mins |

| Boehmite | 3.2 | 3.1 | 2.5 | 1.0 | 1.6 |

| Gibbsite | 66.4 | 68.3 | 68.9 | 71.4 | 70.3 |

| Hematite | 11.7 | 8.1 | 7.3 | 7.3 | 6.5 |

| Rutile | 1.2 | 0.2 | 0.5 | 0.4 | 0.5 |

| Anatase | 3.6 | 2.5 | 2.6 | 2.6 | 1.9 |

| Kaolin | 10.1 | 13.9 | 14.1 | 13.3 | 15.2 |

| Quartz | 3.9 | 3.9 | 4.0 | 4.0 | 4.0 |

| Table 1. Results of quantitative XRD for a 4 kW, lab-based instrument the and the Olympus pXRD at varying collection times. | |||||