Przegląd

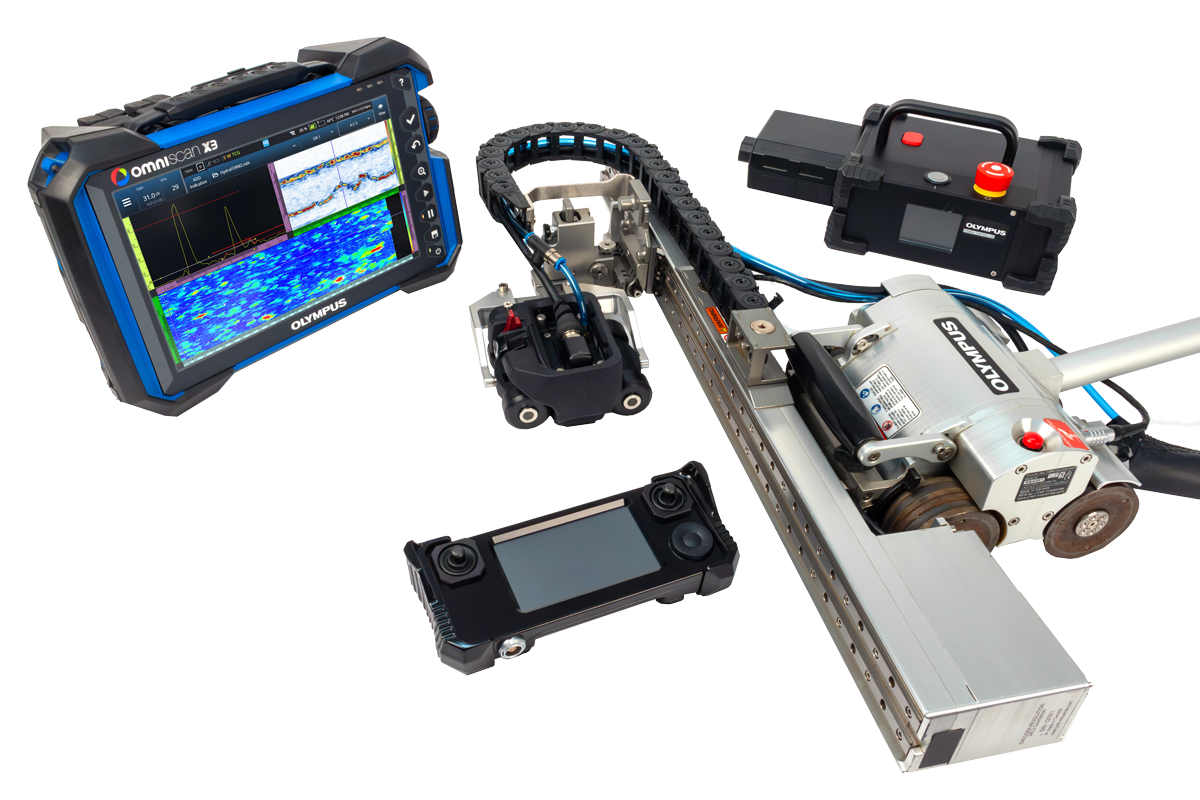

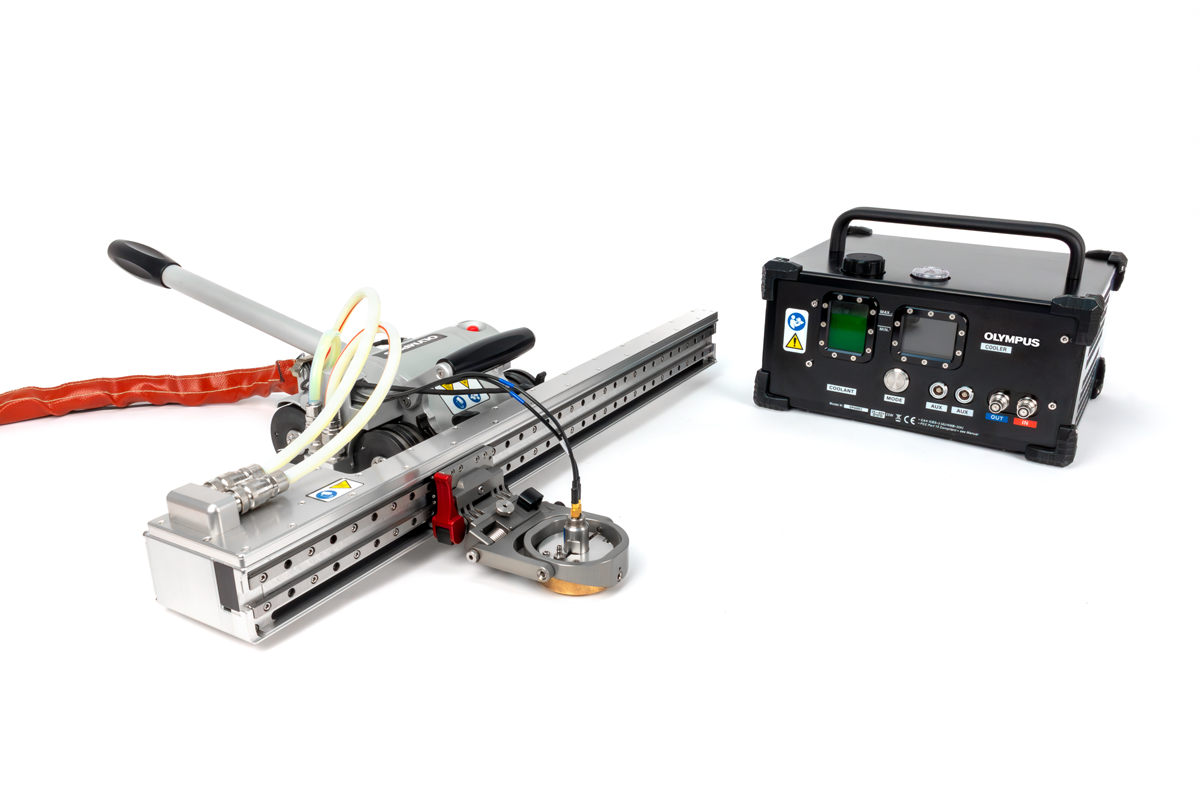

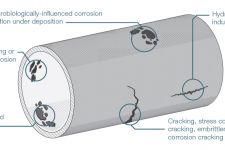

Rugged Motorized Two-Axis ScannerSturdy and reliable, the motorized MapROVER scanner eases and increases the productivity of two-axis scanning for corrosion monitoring applications. Using phased array (PA) ultrasonic technology, the MapROVER system with its robust and easy-to-read touch-screen remote controller simplifies your inspection, eliminating the need for a laptop or complex motor controller programming. Capable of automated PA corrosion mapping around the circumferences of pipes and flat surfaces, the MapROVER scanner’s stable single-motor 4-wheel drive reduces drift to acquire high-quality inspection data with ease. The MapROVER system with the OmniScan X3 flaw detector and HydroFORM A versatile system, different MapROVER configurations are possible depending on your needs. A combined MapROVER and HydroFORM™ corrosion mapping system offers a powerful and efficient solution, enabling PA imaging of remaining wall thickness and midwall anomalies. For high-temperature applications, the MapROVER HT scanner is equipped with a cooling system that enables automated corrosion mapping on surfaces as hot as 350°C (662 °F). Implement advanced techniques such as the total focusing method (TFM) with a MapROVER and OmniScan X3 configuration or opt for a dependable and cost-effective conventional dual UT inspection using our OmniScan™ SX acquisition unit. |

Configurations | ||

| ||

A MapROVER and HydroFORM phased array configuration is our most efficient pipeline corrosion mapping solution. | For inspection of parts with surface temperatures of up to 350°C (662 °F), the MapROVER HT system is an optimal solution for automated corrosion mapping. | Equipped with dual-element UT transducers, the MapROVER scanner and our OmniScan™ SX acquisition unit offers a cost-effective conventional dual UT inspection solution. |

Features

Features

|

Standard Inclusions

|