Głowice Panametrics UT

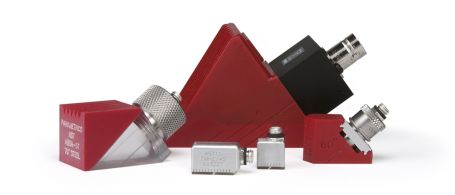

Olympus ultrasonic probes and transducers are used for flaw detection, thickness gauging, materials research, and medical diagnostics. Our more than 4,000 transducer types include contact, dual element, shear wave, delay line, and immersion. If you don’t find what you’re looking for in our transducer catalog, we can create custom and special designs.

Loading...

Przegląd

Angle Beam Transducers & Wedges

Angle beam transducers are single element transducers used with a wedge to introduce a refracted shear wave or longitudinal wave into a test piece.

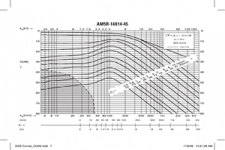

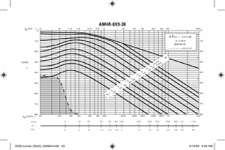

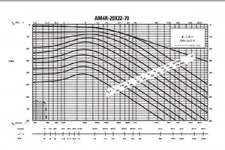

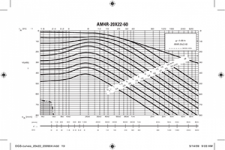

Atlas, European Standard Transducers

Atlas European Standard Transducers feature LEMO connectors, metric unit element diameters, and common frequencies, such as 1, 2, and 4 MHz. They are designed to meet inspection criteria referenced throughout Europe and the rest of the world.

AWS Transducers & Wedges

AWS transducers and wedges conform to the specific requirements of the American Welding Society's Structural Welding Code for angle beam assemblies used in weld inspection.

CDS Wedges

CDS wedges are designed to generate both a 30 degree shear wave and a 70 degree longitudinal wave in steel for sizing ID connected cracking by means of the 30-70-70 technique.

Contact Transducers

A contact transducer is a single element longitudinal wave transducer intended for use in direct contact with a test piece.

Replaceable Delay Line Transducers

A replaceable delay line transducer is a single element Videoscan transducer with a case design configured for use with a replaceable delay line.

Dual Element Transducers

A dual element transducer consists of two crystal elements housed in the same case, separated by an acoustic barrier.

EMAT Transducers

EMAT's are single element transducers that employ a magnetostrictive effect to transmit and receive ultrasonic waves.

High Frequency Transducers

High frequency transducers are single element contact or immersion transducers designed to produce frequencies of 20 MHz and greater.

Immersion Transducers

An immersion transducer is a single element longitudinal wave transducer with a quarter wavelength layer acoustically matched to water.

Immersion Special

Immersion special transducers refer to a variety of transducers that conduct many specific applications such as measuring wall thickness, inspection of aluminum plating, or multi-element array flaw detection.

Immersion Accessories

Immersion transducer accessories aid in immersion applications and techniques. Accessories include bubblers, immersion tanks, reflective mirrors and search tubes.

Integral Angle Beam Transducers

Integral angle beam transducers provide superior signal-to-noise characteristics and contain durable plastic wear. Both Right Microdot and Straight Microdot connectors are available on some styles.

Normal Incidence Shear Wave Transducers

These single element contact transducers introduce shear waves directly into the test piece without the use of refraction.

Protected Face Transducers

A protected face transducer is a single element longitudinal wave contact transducer that can be used with a delay line, protective membrane or protective wear cap.

RTD Transducers

RTD Transducers are well known in the nuclear industry for inspection of critical weld areas in pipes and pressure vessels.

Spot Weld Transducers

Spot weld transducers are specifically designed to provide optimal performance for nondestructive testing of numerous types of spotwelds, including those used in automotive and industrial applications.

Standard Angle Beam Transducers

Standard Angle Beam Transducers have a large element size that allows for inspection of thicker components and provides a large scanning index. They are used with a wedge to introduce a refracted shear wave or longitudinal wave into a test piece.

TOFD Transducers & Wedges

TOFD transducers and wedges generate refracted longitudinal waves in steel for use in applications involving crack sizing by means of the Time of Flight Diffraction technique.

Test Blocks

Calibration and/or reference blocks should be used in every ultrasonic testing application. Standard blocks are available for angle beam calibrations and thickness calibrations of common materials. Blocks made from 1018 steel, 304 stainless steel, and 7075-T6 aluminum are commonly in stock, and custom blocks made from other materials are available on request. All blocks are measured using equipment traceable to the National Institute of Standards and Technology (NIST).

Transducer Cables

Transducer cables are available in a wide variety of types, lengths, and connector styles including BNC, Lemo, UHF, and Microdot.

Couplant & Adaptors

The use of couplant is almost always necessary to provide acoustic coupling between the transducer and the test piece. We offer various types of couplants to suit virtually all applications.

Resources

Broszury

Blog

Uwagi dotyczące aplikacji

Infographics

Seminaria internetowe

Oficjalne dokumenty

Poradniki

Najczęściej zadawane pytania

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.