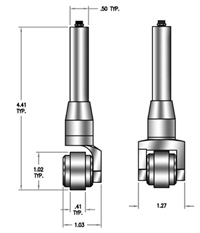

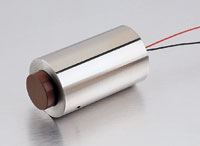

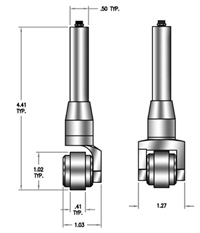

Roller transducers are used in testing metallic or non-metallic materials for bonding/segregation in CFRP/GRP including Kevlar®, rubber friction materials, and high density products such as glass, and metallic and plastic weldments. This series includes roller and contact type transducers at 0.5 MHz and 1.25 MHz. Contact units are available in 5, 10, and 15 mm diameters, while the roller transducers incorporate a 5 mm crystal giving a 10 mm footprint through the replaceable tire. Both

styles are fitted with axial mounted Microdot connectors (other connectors available on request). The roller transducer can be ordered with either a single or dual yoke design.

Frequency (MHz)

|

Size

|

Yoke

|

Wheel Diameter

|

Part Number

|

|

in.

|

mm

| |

in.

|

mm

| |

1.25

|

0.187

|

5

|

Single

|

1.0

|

25

|

RT-0105-16SY

|

1.25

|

0.187

|

5

|

Dual

|

1.0

|

25

|

RT-0105-16DY

|

0.50

|

0.187

|

5

|

Single

|

1.0

|

25

|

RT-0005-16SY

|

0.50

|

0.187

|

5

|

Dual

|

1.0

|

25

|

RT-0005-16DY

|

|

Spare Tires

|

Part Number

|

Wheel Diameter

|

RT-16-10T

|

1.0 in.

|

25 mm

|

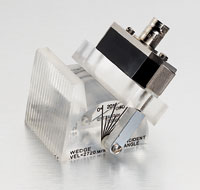

Roller transducers are used in through transmission mode for fast linear scans of parts without the need for an immersion setup. Roller transducers are typically used in applications looking for de-laminations in multilayer materials and are available in either single or dual yoke designs feature a removable and replaceable tire.