Austenitic, Nickel, and Other Coarse Grain Alloy

Przegląd

Austenitic, Nickel, and Other Coarse-Grained Alloys

Corrosion Resistant and Cladded Materials

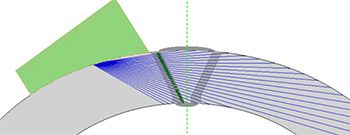

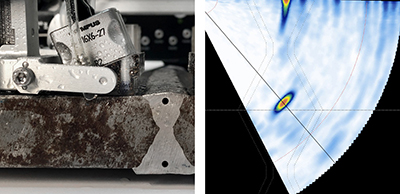

Austenitic and nickel-based alloy weld metals and other coarse-grained anisotropic materials affect ultrasound propagation causing beam distortion, beam scatter, mode conversions, and significantly increased attenuation resulting in a poor signal-to-noise ratio (SNR) as compared to shear wave inspections in low-alloy carbon steels. Inspection of these materials requires the use of dual phased array probes with RL (refracted longitudinal) wedge designs that acoustically insulate the transmitter and receiver beams for improved defect SNR and elimination of wedge echoes. Our Dual Linear Array™ (DLA) and Dual Matrix Array™ (DMA) probes are used with removeable wedges to combine different inspection techniques, such as direct L-wave, creeping wave, RTT (round trip tandem), and other multi-mode techniques, into a single phased array S-scan image for full volumetric weld inspection. |  |

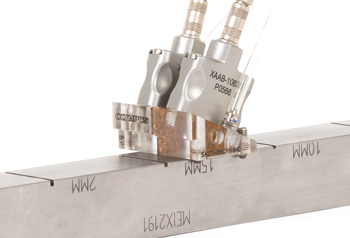

Dual Array Probes (DMA/DLA)

Dual array probes consist of two phased array probes wired to the same connector. They can be either matrix or linear arrays. One probe performs a sectorial scan and the echoes coming back from the defect are captured using the second probe.

A25 |

A27 |

A26 |

A36 | |

| Frequency | 5 MHz | 4 MHz | 2.25 and 4 MHz | 2.25 and 4 MHz |

|---|---|---|---|---|

| Configuration | Dual 16 (Linear) | Dual 32 (16 × 2 Matrix) | Dual 32 (Linear) | Dual 64 (Linear) |

| Aperture | 12 mm × 5 mm | 16 mm × 6 mm | 32 mm × 12 mm | 64 mm × 12 mm |

| Recommended Wedge Series | SA25-DN70L-IH | SA27-DN55L-FD15-IHC | SA26-DN55L-FD40-IHC | SA36-DN55L-FD200-IHC |

| Characteristics | Compatible with the COBRA™ scanner for the inspection of small-diameter pipes (<10 mm thick) | General purpose with excellent overall performance and near-surface resolution (10 mm–40 mm thick) | Optimized for very thick materials (40 mm–80 mm) | Optimized for extra thick materials (>80 mm) |

| Minimum Instrumentation Requirement |

16:64PR (one probe)

32:128PR (two probes) | 32:128PR (two probes) | 32:128PR (two probes) | 64:128PR (one probe) |

Dual UT (TRL) A27 ProbesDual conventional UT probes can be used for surface wave inspection or, in conjunction with DMA probes, for full weld coverage. The detachable wedges enable more versatility for different pipe diameters and stability. |

|

Onboard DMA and DLA Creation and Beam Setup

The OmniScan™ X3 enables you to create custom Dual Linear Array (DLA) or Dual Matrix Array (DMA) probes and wedges. In addition to creating phased array (PA) focal laws, you can also use the scan plan to set up total focusing method (TFM) and phase coherence imaging (PCI) groups. The scan plan accommodates a wide range of geometries, including COD configurations. |

|