Ultrasonic Testing of Carbon Steel Plates and Pipes - NDT

Przegląd

Carbon Steel

Carbon Steel

Pipes and Plates

Olympus’ versatile solution for weld inspections uses a variety of techniques to achieve a productive and efficient inspection on plates and pipes from 4.5 in. OD and up. Phased array, time of flight diffraction, and conventional ultrasonic techniques can be used alone or in combination to achieve full-weld coverage with high probability of detection.

This solution also includes different scanning methods for accurate defect position and sizing. The stability and encoding capability offered by scanners results in better data quality as well as enables code compliant inspections. Scanning is done using different scanners for manual, manual-encoded, semiautomated or automated data collection method.

The Olympus carbon steel weld inspection solution brings together Olympus acquisition units, scanners, probes, and software tailored to your needs. The solutions allow length and depth sizing for code acceptance /rejection.

Compound Scan

|

Olympus’ updated NDT SetupBuilder software now offers the capability to perform compound scan beams. This innovative inspection strategy consists of a mix between sectorial and linear beams and offers many advantages such as:

|

Weld Series PA Probes and Wedges

| The A31 and A32 phased array probes and wedges offer unique features for a new level of performance.

|

High Temperature Inspection

| A high-temperature wedge option compatible with the new A31 and A32 phased array probes and Olympus Mini-Wheel encoder is available upon request. The option enables the inspection of parts with a surface temperature up to 150 ⁰C. |

Passive-Axis Focusing (PAF) Wedges

General Techniques

Scanning Methods

Scanning Methods

Our carbon steel weld solution can be used with different scanning options.

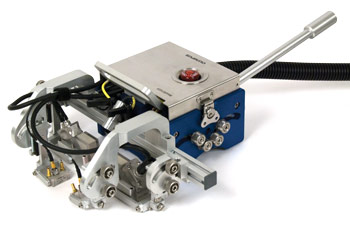

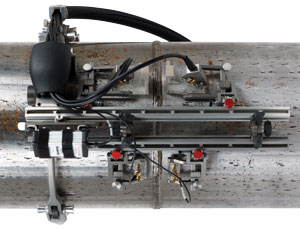

Automated

The WeldROVER scanner is the ideal automated scanning option for inspection of carbon steel weld using one pair of PA probes and up to three pairs of TOFD probes. It provides a faster and more stable movement of the probes for higher rate and more accurate data acquisitions. | For efficient automated scanning of carbon steel welds in difficult-to-reach areas, the motorized SteerROVER scanner enables you to steer the scanner at a distance. Use the SteerROVER scanner with its rugged touch-screen handheld controller to perform reliable phased array (PA) ultrasonic testing of circumferential and longitudinal welds. The optional RECON camera kit assists in navigating the scanner, keeping the weld well centered, and helping ensure that the probes remain in contact with the surface. |

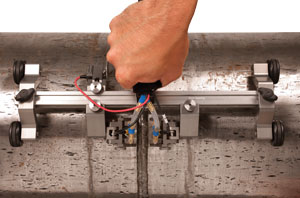

Manual and Manual Encoded

The weld can be scanned manually using one PA probe that can be encoded by attaching a Mini-Wheel encoder or by using a VersaMOUSE hand scanner. |

Semiautomated

|

| ||

|

| ||

|

TechniquesPhased array technique allows multiple beam angles, beam types and beam offset to be generated electronically. This allows greater flexibility for easy adaptation to different type of welds. Conventional UT technique can be an alternative to phased array when very high speed is required or when cost is preferred over flexibility. TOFD can be used alone for fast and simple inspection or as a complementary technique to pulse-echo. Combining phased array and TOFD techniques offers the best performance for most carbon steel weld inspection. Both techniques complete each other for excellent imaging, best POD, and flaw characterization. | Applications

|