Very small metal tube

(1) Application

Advanced metal processing techniques are enabling the manufacture of metal tubes that are thinner than ever before. These tubes will be used in various applications such as medical and semiconductor manufacturing equipment. Depending on the intended use of a tube, its processed shape should be evaluated. Inner surface roughness should be within tolerance to prevent material from becoming stuck while passing through the tube. Areas affected by the drawing or bending process should be checked against the tube surface profile.

(2) The Olympus solution

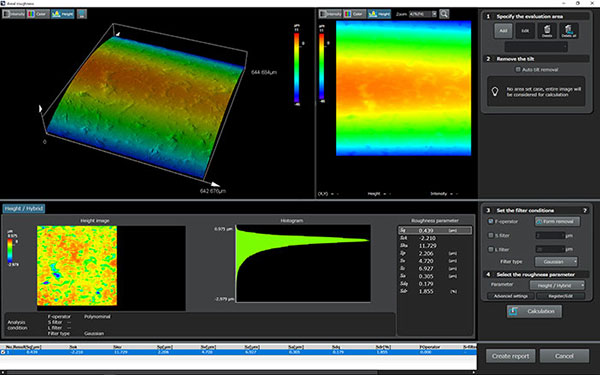

The Olympus LEXT OLS5000 3D laser scanning microscope obtains three-dimensional data with high resolution and precision to enable a 3D display and surface roughness analysis. This microscope has a noncontact laser-optical system. It provides the same line roughness (two-dimensional) parameters as contact-type roughness testers and produces similar measured results. The OLS5000 microscope also provides ISO 25178 compliant, three-dimensional roughness parameters. These parameters enable you to obtain more than line roughness information through surface-area evaluation using 3D images and numerical data. This capability is not available with a conventional noncontact type system. For rounded samples like tubes, the ability to capture the profile of a slope is important. With an optical system optimized for the microscope’s 405 nm wavelength laser, the OLS5000 3D laser scanning microscope can accurately capture slope profiles.

(3) Images

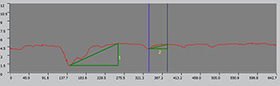

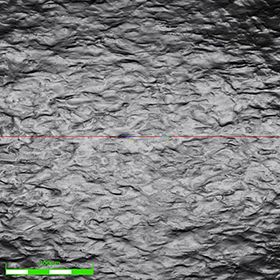

Outer wall profile

|  |

|

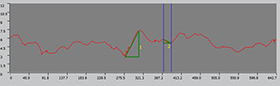

Inner wall profile (in destructive testing)

|  |

|