![]()

Brake Pad Inspection

| Automobile brakes are critical safety components. Modern disc brakes work when the brake pads press against a rotor, causing friction and slowing down the automobile. The friction generates a lot of strain and heat on the pads, so they need to be made of durable materials. Most brake pads are made of a compound of more than 20 materials, and the ratio of each material significantly impacts the braking force and functionality, such as thermal stability, noise, and heat. To help ensure that brakes work correctly, manufacturers carefully observe the pads with a microscope to check that they have been compounded correctly. Depending on the compound, different observation methods are used to inspect them. Digital microscopes are preferred for this application since they offer brightfield, darkfield, differential interference contrast (DIC), MIX (a combination of brightfield and darkfield), and polarized light observation. In some cases, it is difficult to know which observation method is best to use. In these instances, an inspector will typically try all of them to see which works best. On most digital microscopes, this is a slow process since the objective lens needs to be changed each time the observation method is changed. This creates additional work because after the lens is replaced, the observation position needs to be adjusted and the microscope needs to be refocused. |

How the DSX1000 Digital Microscope Makes Brake Pad Inspection More Efficient

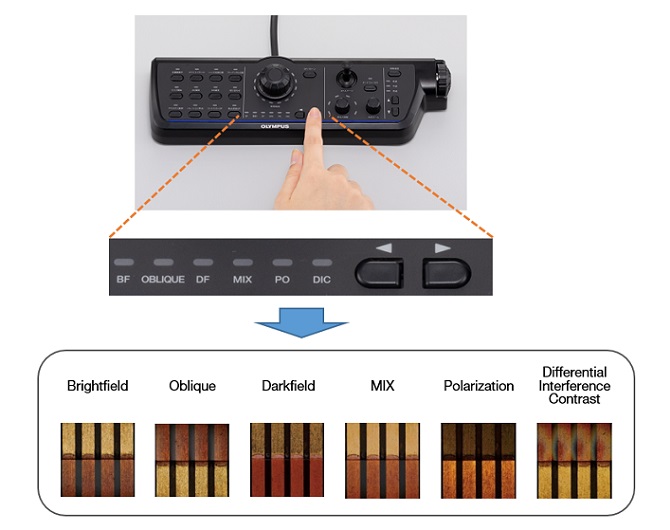

Unlike some digital microscopes, every available observation method can be used with most DSX objective lenses, so you don’t have to swap them every time you switch observation methods. The microscope’s software has a 'best image' function that displays thumbnail images of your sample under six different observation methods, making it quick and easy for an inspector to choose the best one.

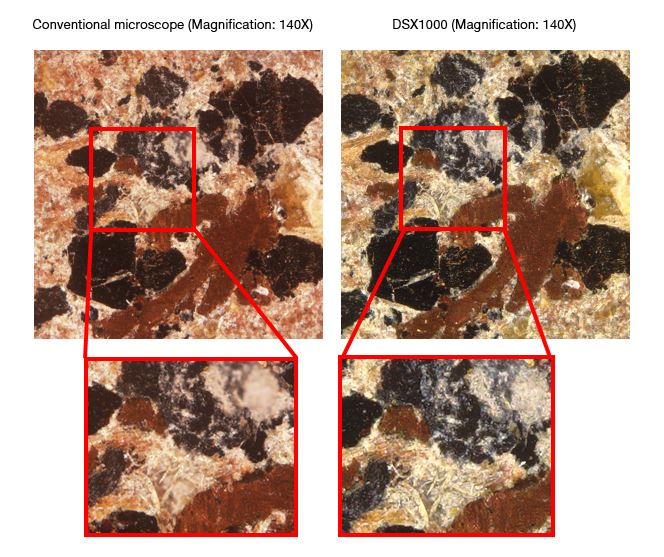

Images

The images below show a sample captured with a conventional microscope compared to one obtained with a DSX1000 digital microscope (polarized light observation).

Due to the low-resolution lens on the conventional microscope, it is difficult to identify the color differences among different materials in the brake pad compound. In the image taken by the DSX1000 microscope, the material compounding state is clearly visible.

*To guarantee XY accuracy, calibration work must be undertaken by an Olympus service technician.