In the previous installment of this series on gearbox inspection, I underlined the importance of proactive maintenance for wind turbine operators. Videoscopes play an important role since they act as an extension of the eyes, enabling you to look inside complex parts such as gearboxes. But simple visualization is just the beginning—with the right features, a videoscope can be an indispensable tool in your maintenance strategy to help keep the wind turbine running longer.

1. High Image Quality to See Tiny Defects and Pitting at an Early Stage

The IPLEX™ G Lite videoscope offers high-resolution images and intelligent illumination so you get consistently clear and bright images with reduced glare. Our WiDER™ image processing also enhances the dark areas that are difficult to see because of reflective surfaces. This enables you to check gears for cracking and chipping and inspect the bearings for scratches, pitting, indentations, and any other imperfections.

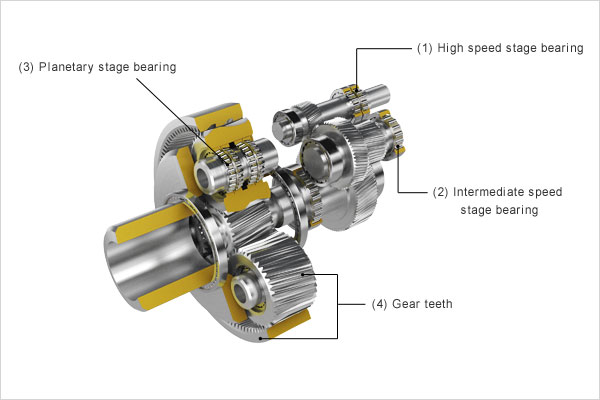

High-speed stage bearing |  Planetary gear with damage |  Gear teeth |

When to inspect the gearbox: I recommend inspecting new gearboxes with your videoscope to establish a baseline and record its original condition. Then inspect it again a year after it has been in operation to properly monitor any degradation. A new gearbox should not have any scratches in the gear teeth and roller bearings, and all the moving parts should degrade gradually during operation. Regular periodic inspections during low wind season can also help in maintenance planning.

Later on in this post (see #5 below), I share some handy software features that facilitate long-term record keeping for condition monitoring gearboxes using a videoscope.

2. Easily Interchangeable Scopes with Different Diameters to Accommodate Various Sized Components and Spaces

Since gear teeth are relatively large, you need to use a 6 mm or 8 mm diameter scope with bright illumination to get a good overview of their conditions. To detect tiny defects, such as early-stage micro pitting, a near-focus observation at 5 mm or closer is very important.

On the other hand, you need a 4 mm diameter scope to inspect the roller bearings since the gap between the rollers and races is narrow in some gearboxes. To properly see the surface of the rollers and races in this narrow space, you need a near-focus optical performance of at least 15 times magnification at a 3 mm distance from the surface for detailed observation of bearings.

The IPLEX G Lite Wind Turbine Inspection Kit comes with both 4 mm and 6 mm diameter scopes offering advanced imaging features to help you capture high-quality, up-close images for gear teeth and bearing inspection.

3. Oil Clearing Scope Tip Adaptor and Responsive Tip Articulation to Navigate in Tight Oily Spaces inside Gearboxes

Gear oil is everywhere in the gearbox, and it makes the image blurry when it gets on the videoscope lens. Inspectors can waste half of their gearbox inspections cleaning and repositioning the scope lens. We developed an optical adaptor that draws excess gear oil away from the lens using capillary action. The result is clear images you can see for yourself.

Inspecting a gearbox bearing without an oil clearing adaptor (left) and with an oil clearing adaptor (right)

Tips for gearbox insertion: Using a guide tube and other accessories can help ease this complicated insertion job.

- Flex-and-Stay guide tubes, which are pliable yet rigid, can be used to reach the planetary carrier, low-speed (LS), intermediate speed shaft (IMS), and high-speed (HS) bearings while avoiding contact with oily gearbox parts.

- It also helps to have highly responsive scope tip maneuverability, such as our TrueFeel™ articulation, to facilitate a fast, efficient approach to the target and precisely aim the lens using the remote control.

- Preshaped copper or plastic tubes are also useful for repetitive inspections if you know the gearbox’s internal design.

- A generic tripod with articulating arms and a magnetic base can be attached nearby to help hold the guide tube while you operate the insertion tube and controller.

- I recommend attaching one end of a wire to the guide tube and hooking the other end on the outside of the gearbox—that way, if you accidentally drop the tube, it doesn’t fall under the scaffolding to the bottom of the nacelle.

The IPLEX G Lite Wind Turbine Inspection Kit includes everything you need for efficient and accurate gearbox inspections, including oil clearing tips, a rigid sleeve set, and a pliable, yet rigid guide tube.

4. Rugged and Ultra-Portable to Withstand the Demands of Up-Tower Inspections

The IPLEX G Lite videoscope is compact, battery-powered, and weighs only 1.15 kg (2.5 pounds). Its portability helps you work more efficiently in those tight spaces inside a wind turbine nacelle. The unit is dust and drip proof and built to withstand 1.2 m (4 ft) drops and vibration. So accidental drops or oily machinery shouldn’t be an issue.

The videoscope’s case is rugged and smartly designed. Whether you carry or ship the videoscope to the wind tower site, you can fit all necessary items in the case, and its strong enough to ship using commercial transportation companies. The case is small to fit in the wind turbine service lifts or to hoist from the belly hatch of the nacelle.

5. Effectively Manage Your Inspection Data

The true value of videoscopes for wind turbine operators lies what they reveal during periodic inspections, making them more than just a complementary tool to remote system or condition monitoring system (CMS) data.

Remote monitoring systems can help predict gearbox failure up to 30 days in advance, but the delay to repair a gearbox can be up to 5 months or more. Time and costs can be saved by using a videoscope to perform regular inspections and take images of parts to compare them over time. These images can help you identify specific points of degradation or a defect at an early stage. Operators can use this data to direct their maintenance activities and part replacement plans.

To organize your gearbox inspection data, our InHelp™ inspection assist software, a companion PC software for IPLEX videoscopes, has features to streamline the process:

Identify the component’s location in the gearbox when the image is captured

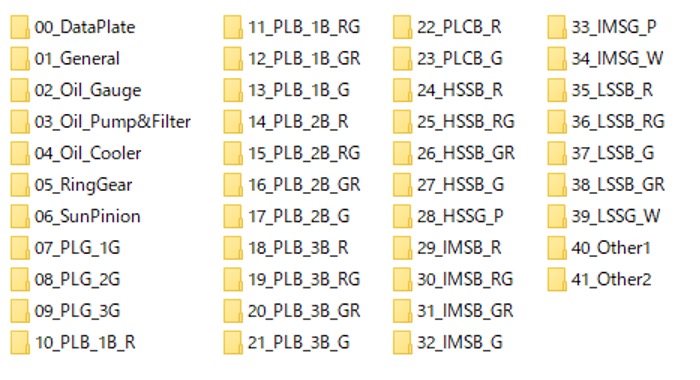

In close-up images captured by a videoscope, gear teeth and bearings tend to all look the same. In a typical 2 MW wind turbine gearbox, there are nine gears with several gear teeth to inspect as well as 20 bearings. To eliminate the need to take notes as you go, Olympus came up with an innovative system. Using the InHelp software, you simply prepare image folders on an SD card for the location of each gear and bearing. Below is an example of the folder set for a typical wind gearbox:

As you proceed with the inspection, you change the active folder as you capture images. The images are stored in the active folder and the image file name is assigned as “FolderName_5DigitNumber.jpg”. This way, the images are neatly sorted when you finish your inspection. Then you can copy the complete inspection image data set to your hard drive or server.

When you want to make a report, it’s easy for you to identify each location without opening all the images. If you need to send the image file to your managers or partners, the file name helps clarify the location of any potential degradation or defects.

Add the inspector’s analysis in the captured images

The IPLEX G Lite videoscope’s “Filemark” function enables you to store comments and evaluation information with the image file in 3 easy steps:

- Confirm or change the folder location to store the image in the correct location.

- Add your inspection assessment using five different mark levels for easy reviewing.

- Add your comment from the preset selection for notes and reporting purposes.

Easily include images in your report with the report generation tool

Olympus’ InHelp software helps you simplify your inspection report generation. Originally designed to view images and defect measurements on your PC, InHelp software now has additional functions, such as wireless image download from your IPLEX videoscope (using a wireless SD card) and inspection report generation.

The “Show Below” function displays all the thumbnail images in the multiple folders and sorts images based on the mark they were given during the inspection (using the Filemark function). When you want to add the image to your videoscope report, you can simply check mark it. Using a customized report template, you can generate your report with the checked images.

You can download the InHelp Viewer software for free from the Olympus IMS website. And don’t hesitate to contact us to help you make your customized templates.

Up next: A blog post containing the basics on inspecting wind turbine gearboxes using a videoscope. It will also provide a guide to borescope training programs for wind power owners and operators.

Stay tuned!

Related Content

IPLEX™ G Series Wind Turbine Inspection Solutions