Our CIX100 cleanliness inspector streamlines technical cleanliness inspections with a step-by-step workflow. While much of the inspection is automated, the system also provides review tools to help operators manually evaluate and revise the results.

One of these tools is real color mode, which shows the actual color of particle contamination.

Real color mode is helpful for confirming if a particle is truly metallic or nonmetallic. Metallic particles are important to recognize in technical cleanliness inspections since they are harder and potentially more damaging to the components being tested.

Read on to learn how real color mode works.

Confirming Metallic Particles Using Real Color Mode

The CIX100 system has an innovative polarization method that detects reflective (metallic) and nonreflective (nonmetallic) particles in one scan. The reflecting particles appear blue in polarization, so you might conclude that each blue particle is metallic.

Real color mode enables you to check the results.

In real color mode, the blue color of reflective particles is omitted, and the true colors of all particles are shown in the brightfield image. Materials that are actually blue remain blue. In contrast, metals show their metallic shine and the reflections typical for the material.

With these helpful visuals, you can better understand the nature of each particle and quickly confirm the particle type as metallic or nonmetallic.

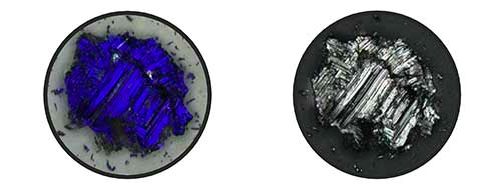

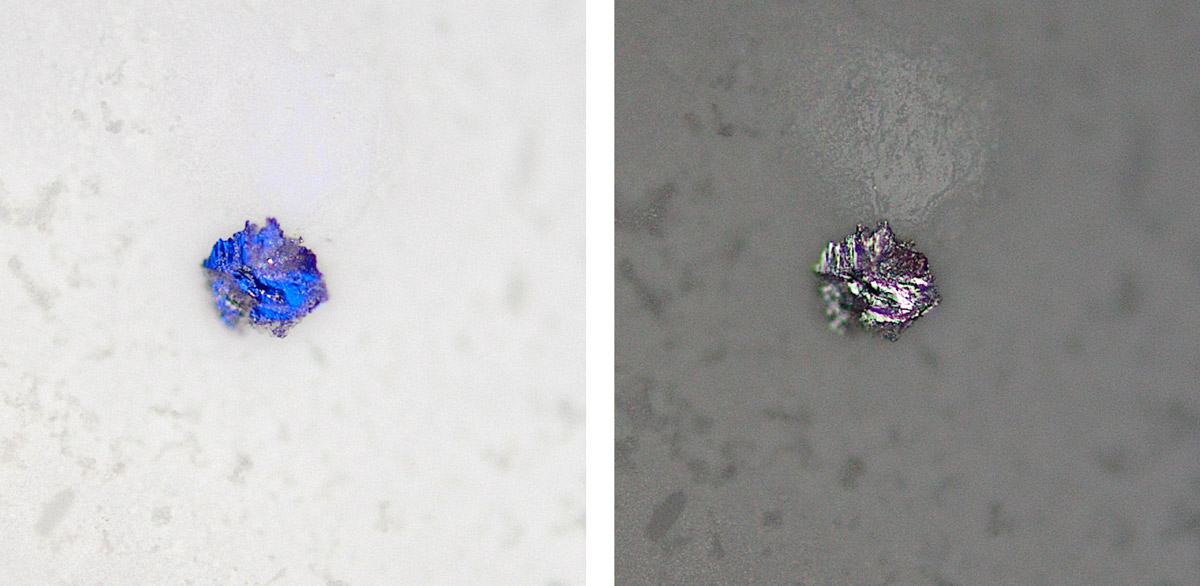

Consider the example images below of three particles. All three particles show as blue in color during inspection, indicating that they are reflecting (metallic). Real color mode shows the true colors of the particles: the first two particles have a metallic shine (confirmed metallic) and the third particle lacks a metallic shine and is actually blue (confirmed nonmetallic).

Left: particle as shown by the system during inspection. Right: brightfield image of the same particle shown in real color mode. The metallic shine of the particle shown in real color mode confirms the particle is metallic.

Left: particle as shown by the system during inspection. Right: brightfield image of the same particle shown in real color mode. The metallic shine of the particle shown in real color mode confirms the particle is metallic.

Left: particle as shown by the system during inspection. Right: brightfield image of the same particle shown in real color mode. In real color mode, you can see the particle lacks a metallic shine and is actually blue. The particle is confirmed as nonmetallic.

Combining Real Color Mode and Extended Focus Imaging

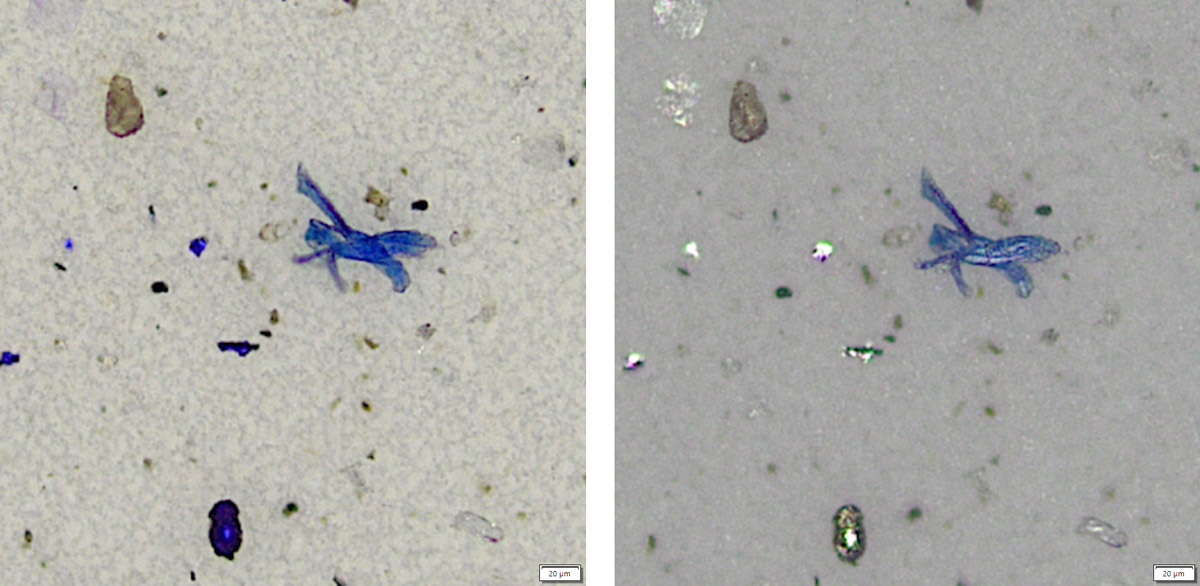

Real color mode can also be combined with the extended focus imaging (EFI) mode. In short, EFI mode offers focus stacking for full depth focus. Combining the two modes means the particles are fully in focus and in their actual color, enabling you to get a better look at the particle characteristics.

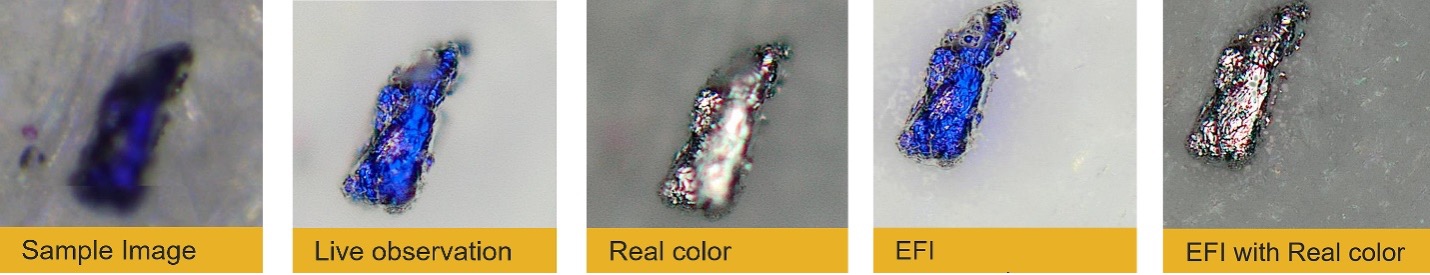

A particle in various views using the CIX100 system. EFI and real color mode (right image) enhances the image by showing the particle in focus and in its actual color. Image courtesy of Europafilter Norge.

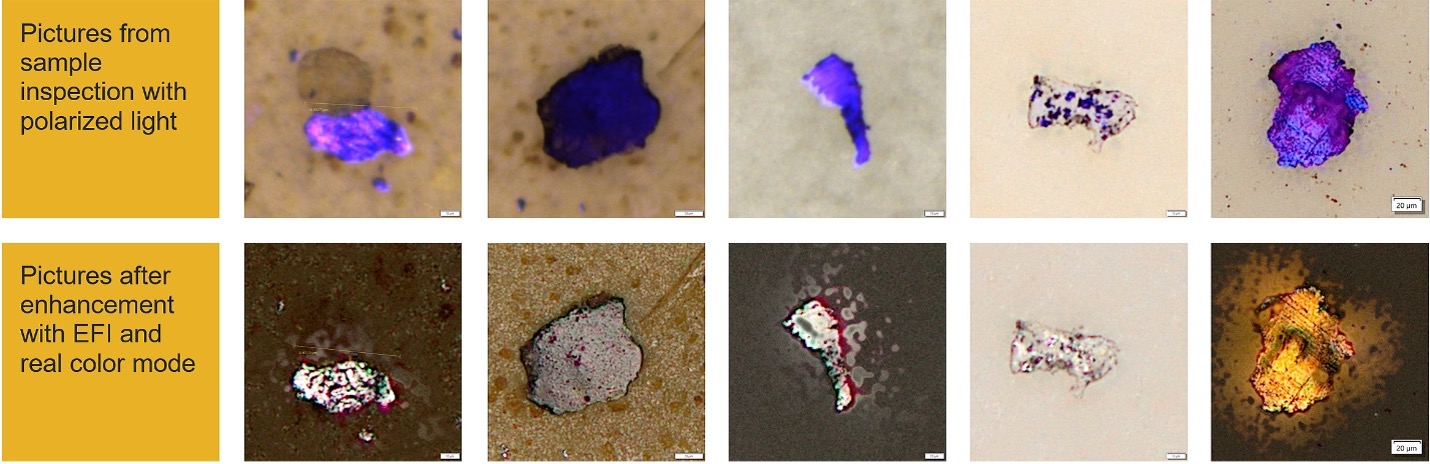

The example images below show how combining these modes helps with particle identification. While all the particles are reflecting in the top row, applying real color mode (bottom row) shows only three of the particles are metallic. From left to right, the first (steel), third (steel), and fifth (brass) particles are metallic. The second and fourth particles are nonmetallic.

Without the real color mode, all particles in the top row would rank as metallic as they are reflecting and appear blue in polarization. The bottom row shows the same particles using real color mode. From left to right, the first (steel), third (steel), and fifth (brass) particles are metallic. The second and fourth particles are non-metallic. Image courtesy of Europafilter Norge.

Learn more about combining EFI and real color mode in the video below:

Identifying Contaminant Particles Based on Particle Color and Shape

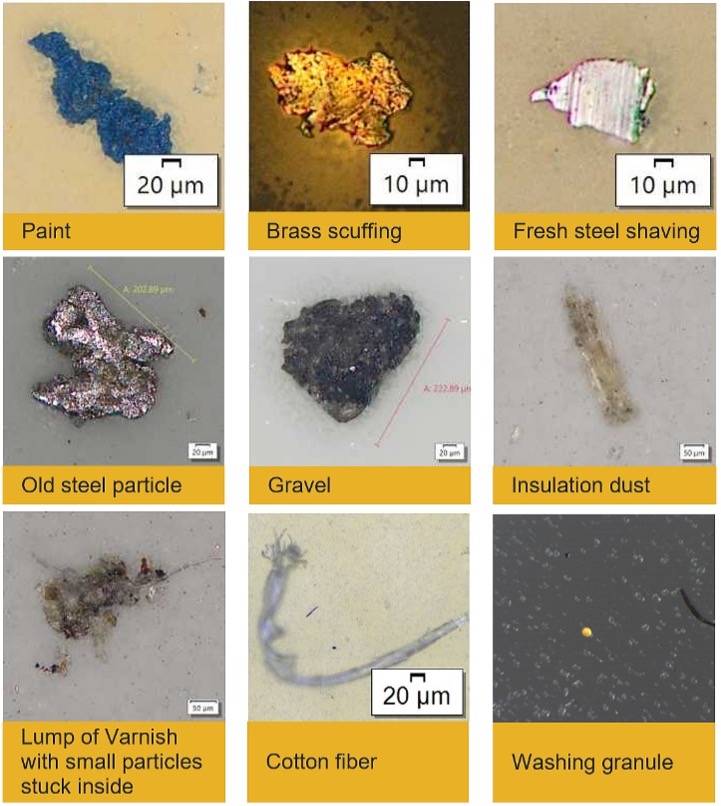

Seeing the color and shape of a particle can help you figure out its material, age, and other characteristics. This information makes it easier to determine the source of the particle contaminants and take swift countermeasures.

Consider the following examples from an oil cleanliness analysis.

Brass: If you find brass in your oil, you could have problems with your pump, as pump gears are often made of brass.

Fresh steel shaving: A fresh steel shaving could come from a sliding machine part, a steel pump, or a bearing.

Old steel particle: An old steel particle (no sharp edges) means that the particle has traveled around the system several times. The sharp edges become round as the particle is smashed through the system.

Gravel or insulation dust: If you find gravel or insulation dust, you may have a problem with the air filter on your reservoir tank.

Cotton fiber: A cotton fiber can come from cleaning clothes.

Paint plaque: A paint plaque could indicate a problem with the reservoir tank. The paint inside the tank could have flaked off, or the particle entered when the system was opened for maintenance or oil exchange.

Washing granule: A washing granule could be from cleaning a part in the system.

Lump of varnish: A lump of varnish with small particles stuck inside could be from old oil.

Examples of particle contamination found during an oil cleanliness analysis. Particles are shown in real color mode using the CIX100 system. Image courtesy of Europafilter Norge.

Detailed Images of Particle Contamination for Technical Cleanliness Inspections

Thanks to high-quality optics, the CIX100 system provides detailed images of each detected particle to support the identification of particles. Thumbnail images of every contaminant detected by the system are linked with dimensional measurements, making it easy to review the data. Simply select a thumbnail image to automatically drive the system to this contaminant.

Thumbnail images of particle contaminants are displayed on the intuitive user interface of the CIX100 system

Learn more about the intuitive review tools in our post, 7 Capabilities That Make Technical Cleanliness Inspections Easy for Novice Operators.

Related Content

Oil Contamination and Analysis—Expert Insights on an Invisible Problem

Perform an Efficient Cleanliness Analysis with 3 Added Capabilities

7 Capabilities That Make Technical Cleanliness Inspections Easy for Novice Operators

Get In Touch