Basic Ultrasonic Testing Principles Still Apply

To start, it is important to remember that the total focusing method (TFM) is subject to the same physical laws that govern conventional ultrasonic testing (UT) and phased array (PA). Electronic focusing with phased array is the ability to converge the multiple wave fronts of the individual probe elements in a small area, which is called the focal point. Such convergence is only possible inside the near field of the phased array probe.

The end of the near field corresponds to the last maximum of the pressure field along the propagation axis of an unfocused ultrasonic beam. It is defined by the probe parameters, such as element size and frequency, as well as the velocity of sound in the material. In PA, the near field is the zone where focusing can happen. Outside this range, the inspection is considered unfocused, and the beam amplitude and resolution will degrade with the sound path just like with conventional UT. With TFM, the same focusing and near field limits apply, meaning that what is true for PAUT, is true for TFM.

Probe Characteristic Considerations and the Focusing Capability Trade-Offs

A probe’s frequency, element size, and number of elements are some of the factors that have an impact on the setup and the quality of the inspection. For example, since the near-field length is directly proportional to the probe frequency and aperture size, a probe with a higher frequency and a larger active aperture is capable of focusing further away from the probe face, thereby providing a larger focused region and improved TFM imaging. On the other hand, the near-surface resolution is negatively impacted.

Relying on experimental testing to determine the ideal probe for TFM setups is impractical due to all the variables involved. This underlines why a modeling tool is essential for your TFM inspection configuration.

The Necessity of Modeling Tools for Selecting Probes for TFM Inspection

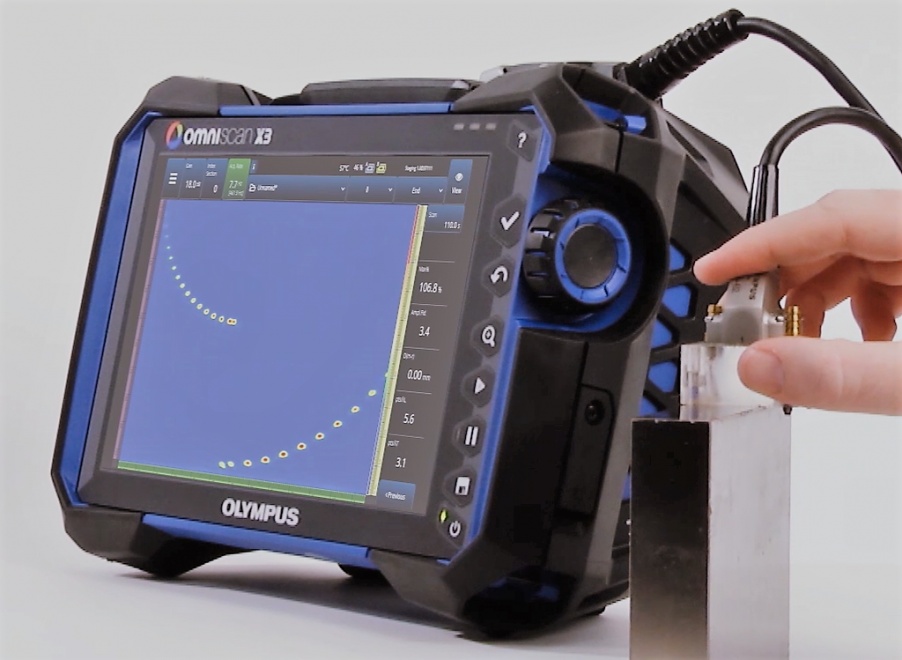

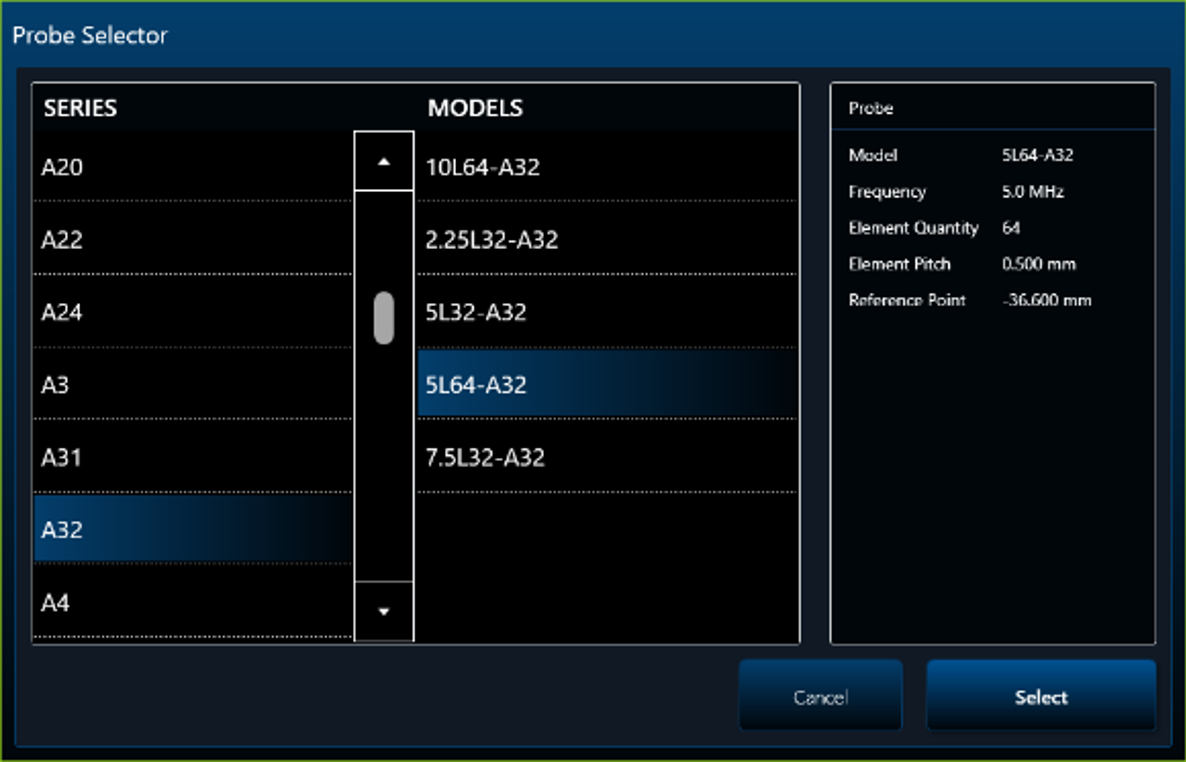

The Acoustic Influence Map (AIM) modeling tool onboard the OmniScan™ X3 flaw detector helps you predict the quality of the resulting TFM signal. It displays the expected ultrasonic response provided by a given probe and wedge combination for a particular reflector using a selected wave set. In this way, it can help you make the right choices, including the appropriate probe and wedge, for your setup.

If you think of the AIM as a heat map showing where the amplitude response is the strongest, the Sensitivity Index is like the maximum temperature. There is no hard limit on how “hot” it can get, but the hotter the better. By comparing the predicted Sensitivity Index of the AIM generated for a given set of parameters (i.e., the selected probe, wedge, reflector shape and angle, wave set, etc.) to another AIM, you’ll have a good idea of which configuration will perform best for your inspection needs.

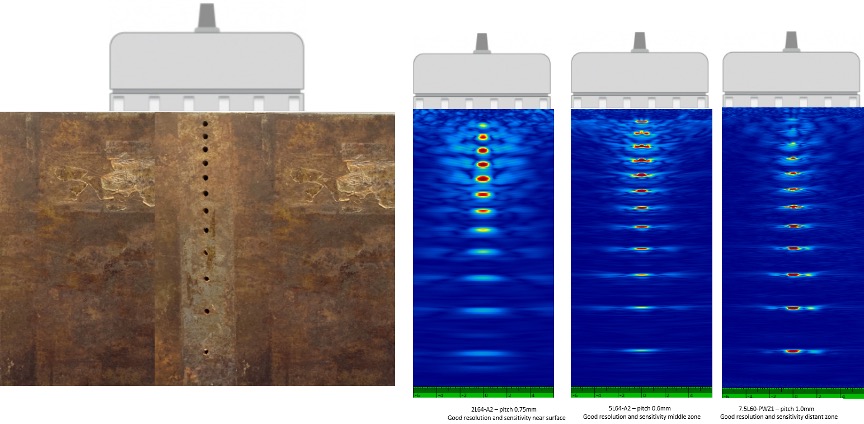

AIM: An Example of the Impact of the Probe Pitch on the Sensitivity for TFM

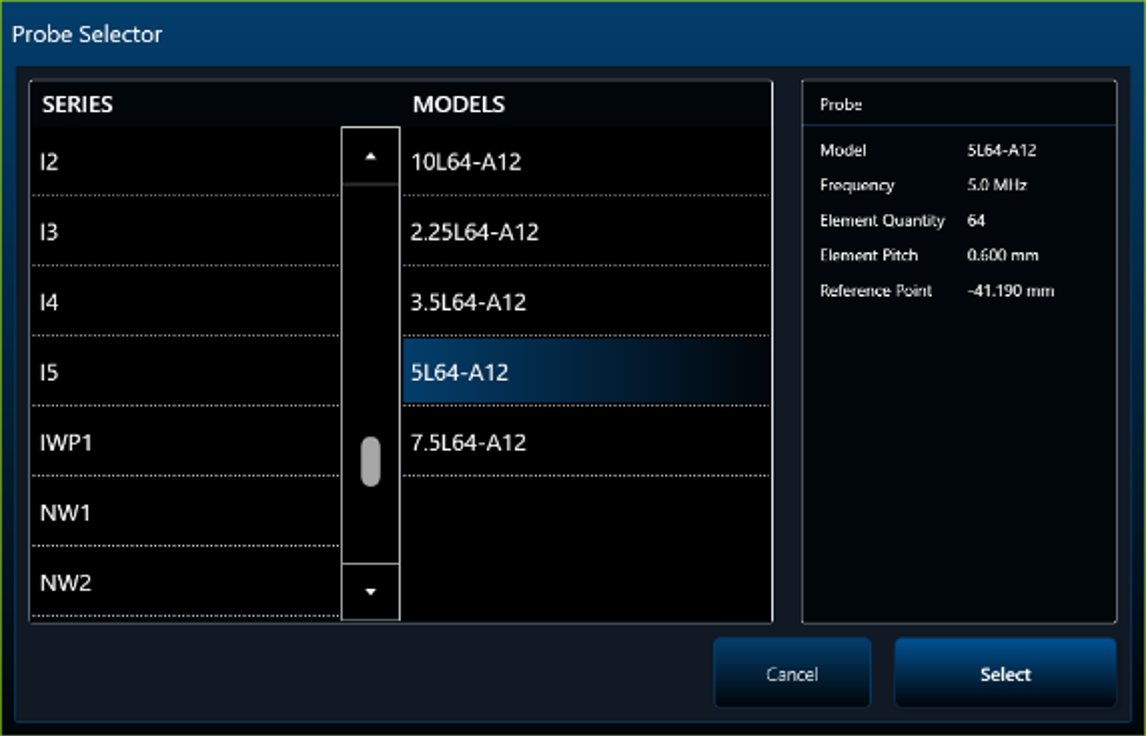

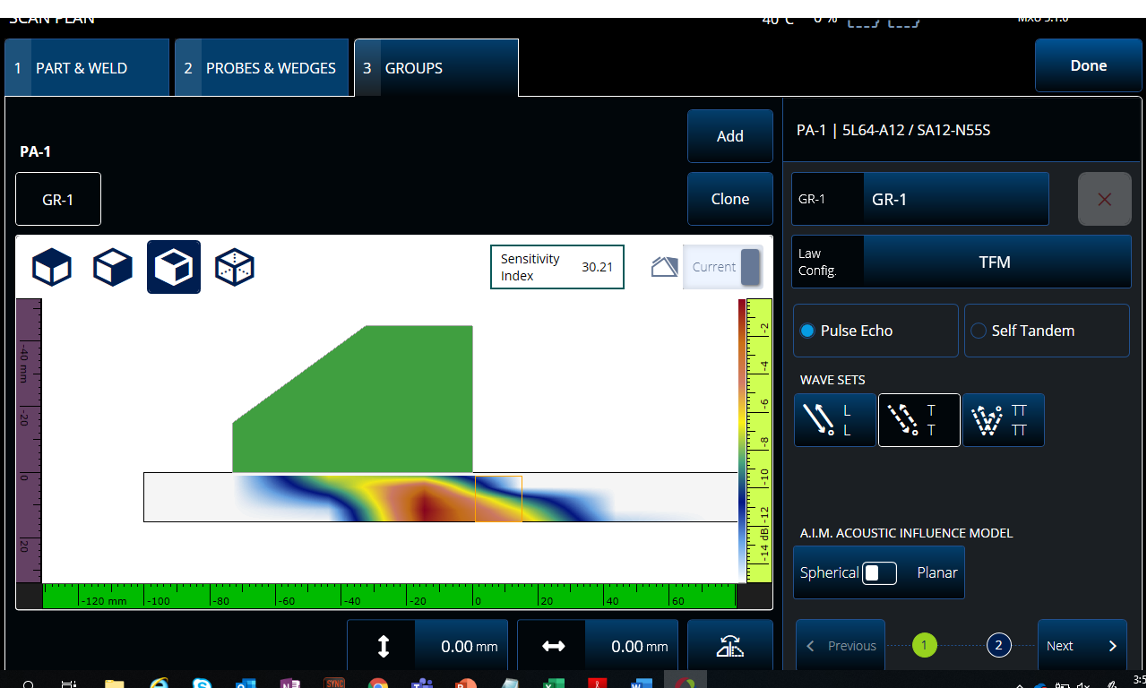

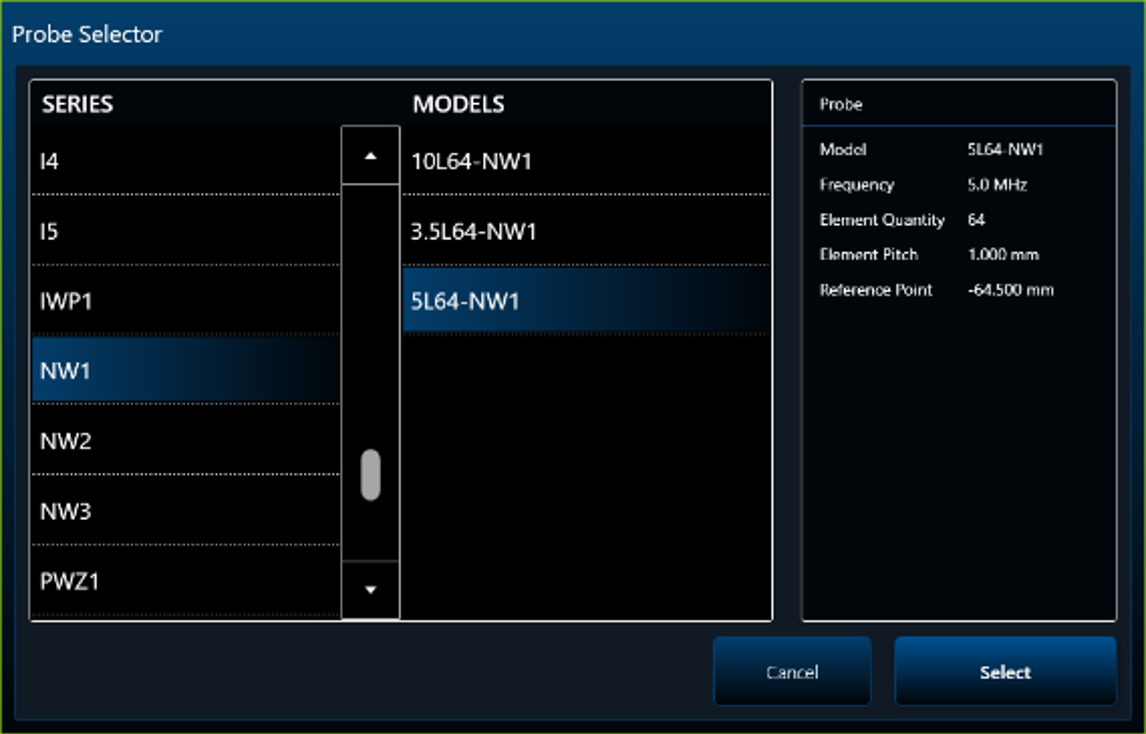

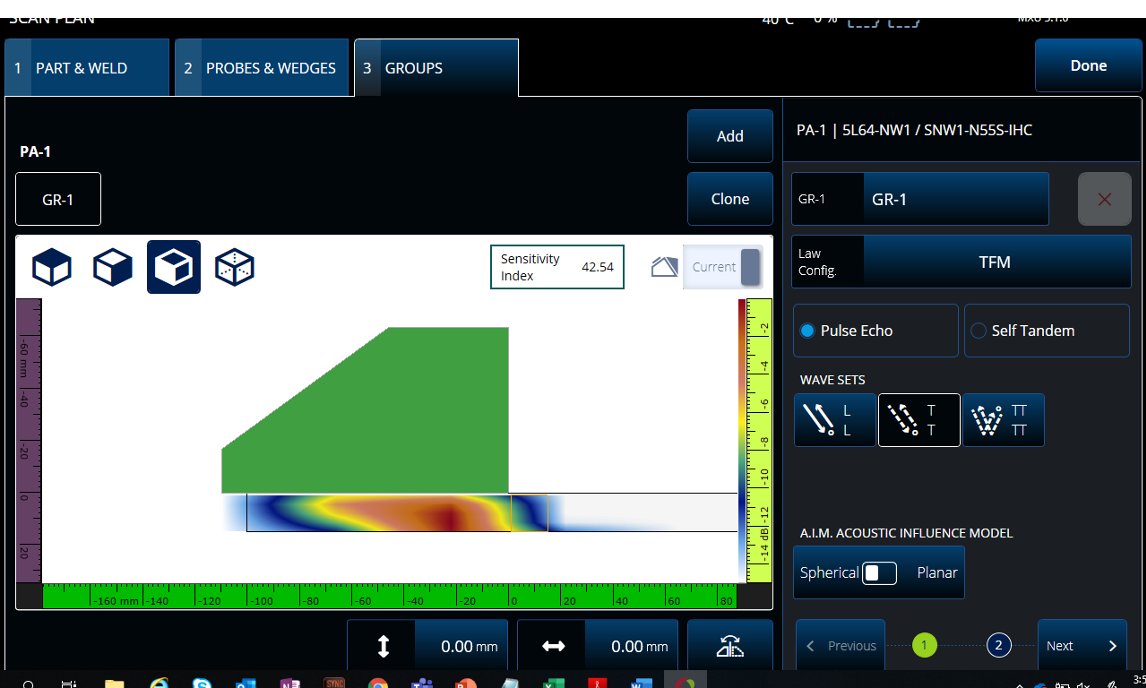

The following screenshots are AIM simulations where the probe frequency (5 MHz) as well as other settings are the same but the element sizes (pitch) are different. In this example, when the size of the elements is increased on the active axis, the Sensitivity Index also increases.

|  |

5L64-A32 probe model: 32 × 10 mm total active aperture, 0.5 mm pitch, 10 mm elevation, TT pulse-echo wave set |

|  |

5L64-A12 probe model: 38.4 × 10 mm total active aperture, 0.60 mm pitch, 10 mm elevation, TT pulse-echo wave set |

|  |

5L64-NW1 probe model: 64 × 7 mm total active aperture, 1.00 mm pitch, 7 mm elevation, TT pulse-echo wave set |

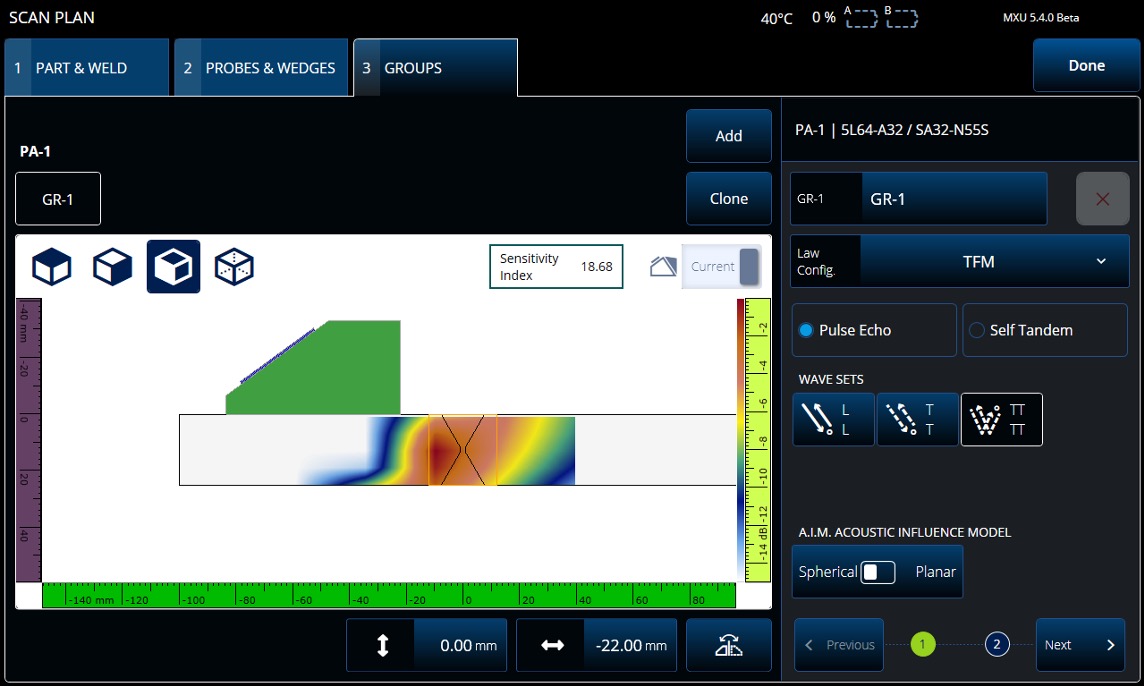

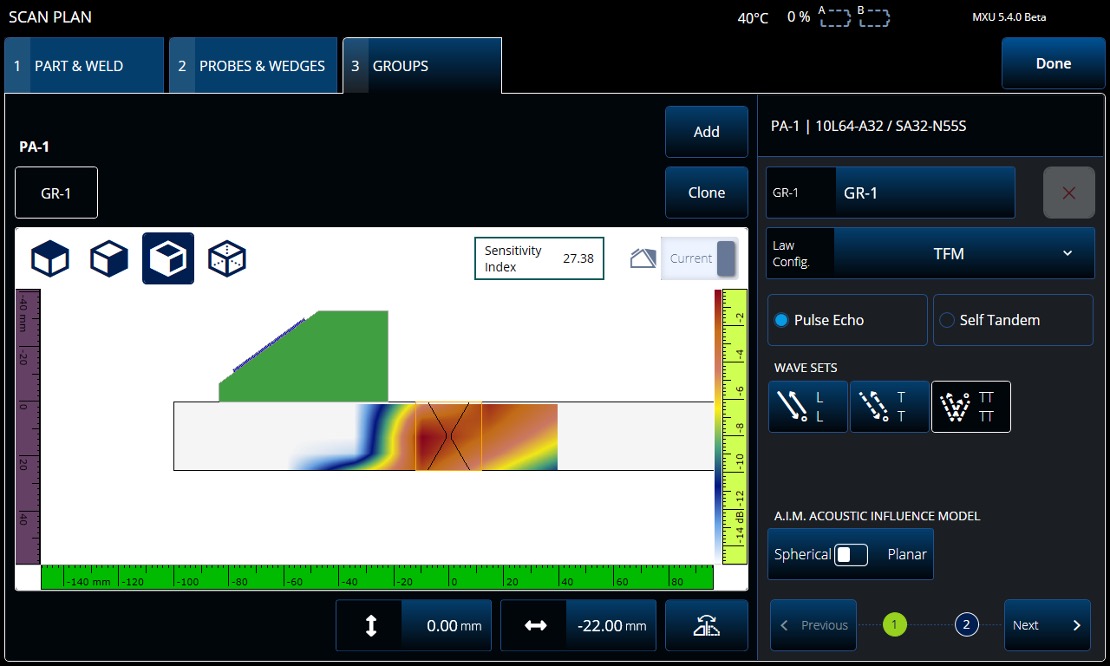

AIM: An Example of the Impact of Probe Frequency on the Sensitivity and Coverage

Probe frequency also has an impact on the AIM simulation, and ultimately the TFM inspection: the higher the probe frequency, the further away the transition from near field to far field. Notice in the examples below that the Sensitivity Index value is higher with the higher frequency probe and the AIM coloring is more consistent throughout the full skip meaning less variation in the amplitude, and therefore indication size, with the increasing sound path.

5L64-A32 probe model: 5 MHz frequency, 32 × 10 mm total active aperture, 0.5 mm pitch, 10 mm elevation, TT-TT wave set

Sensitivity Index: 18.68

10L64-A32 probe model: 10 MHz frequency, 32 × 10 mm total active aperture, 0.5 mm pitch, 10 mm elevation, TT-TT wave set

Sensitivity Index: 27.38

In addition to a practical modeling tool such as AIM, proper preparation and a good TFM scan plan should always include probe strategy and feasibility tests to ensure the area of interest is covered adequately and the signal quality is good.

Related Content

4 Essentials for Building Your Code-Compliant TFM Strategy for Weld Inspection

Video: FMC-TFM Basic Principles

Get In Touch