IPLEX RX/ IPLEX RT

Overview

The IPLEX RX/ IPLEX RT are lightweight industrial videoscopes that feature the unique PulsarPic image processor to produce high-resolution and bright images. They have 6.5-inch screen with an anti-reflective daylight-view monitor.

Exceptional Image Quality to Improve Inspection Quality

Good image quality

The IPLEX RX and RT feature good image quality of our videoscopes. Our unique PulsarPic image processor reduces noise and sharpens images, resulting in the exceptionally high resolution image.

The IPLEX RX and RT faithfully and brightly reproduce very small defects, and the sharp and clear images enable accurate and reliable inspections.

Sharp and clear images with less noise

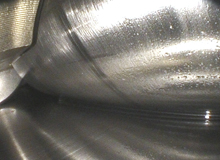

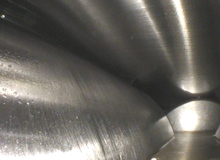

Drill Hole |  Bearing of wind gearbox |  |

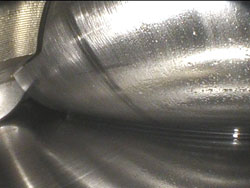

Brighter Illumination System

The IPLEX RX and RT feature a new LED illumination system that is approximately twice as bright as conventional videoscopes, while dynamically adjusting light output to reduce halation when metal or reflective surfaces are inspected.

The PulsarPic image processor interacts intelligently with our illumination system to deliver an optimized amount of light and gain enhancement to provide images that are very clear and sharply defined.

Good images of both dark and light area

Turbine blades |  Combustion chamber |

See other application images >>

Still Images and Movies as Crisp as Live Images

Comparison of image sizes |

The IPLEX RX and RT can record inspected images to a removable USB flash drive as JPEG still images and MPEG–4 movies.

The improved image quality of recorded images and movies enables accurate image diagnosis not only in the field but also at the office with the use of our free image management software, InHelp viewer. |

Large Monitor Providing Easy Yet Accurate Inspections

| The compact IPLEX RX and RT are equipped with a 6.5 in. monitor. The large monitor displays small defects clearly from a comfortable distance for inspectors for easy identification. |

Optimized Image Gradation

The IPLEX RX features our unique image processing capability, WiDER, which brings out the darkest areas of an image without washing out the details of the brighter regions. The innovative technology provides optimum inspections of large areas or even highly reflective areas.

In addition, the IPLEX RX is equipped with sharpness and color adjustment functions to create optimal images depending on objects and applications.

Sharpness: Level ‐1 Color: Standard/ Normal gain setting |  Sharpness: Level 2 Color: Vivid/ WiDER gain setting |

Operation With Ease for All Remote Visual Applications

Compact and Portable Design

The IPLEX RX and RT weigh just 2.9 kg/ 6.4 lb including the two‐hour operating Li‐ion battery. The compact and portable design allows you not only to easily ship or transport the IPLEX RX and RT to inspection sites but to smoothly carry them to difficult-to-access locations.

The IPLEX RX carried up a ladder with a shoulder strap |  The compact and neat design is easy to carry with one hand |

Comfortable Inspections in Optimal Styles

The versatile design of the IPLEX RX and RT offers comfortable use to almost anyone. The pivoting handle of the monitor can change into a stand during inspections, and allows you to place the videoscope wherever you want to optimize viewing distance and angles. The video output capability of the IPLEX RX and RT enables inspections in a group or from remote locations by connecting the external monitor. Furthermore, the IPLEX RX and RT can be used while being carried with a shoulder belt or connected onto a tripod.

The same inspected image is shared between two operators with an external display connected to the IPLEX RX for remote observation |  The IPLEX RX sits on a surface using its pivoting handle to angle the image just right |

Wide Scope Variation

| The IPLEX RX and RT offer a range of scopes, allowing you to choose the right one to fit the job. Scopes are available in diameters of 4.0 mm and 6.0 mm, and in various lengths ranging from 2 m to 20 m. |

Smooth and Accurate Approach to a Target

TrueFeel articulation providing a precise and controlled bend at the distal end |

The innovative articulation technologies equipped on the IPLEX RX and RT allow for smooth and accurate approaches to the most demanding inspection paths.

The improved TrueFeel articulation controller features precise and quick scope tip articulation by just light-touch operation, achieving smooth navigation through intricate paths. The insertion tube is designed with the unique Tapered Flex to optimize both the scope stiffness and flexibility for excellent scope maneuverability. |

Quick and Easy Operation

The handheld controller boasting Quick Access keys capable of over 14 actions in a single touch | The most common operations such as scope articulation, image adjustment and recording can be easily activated by pressing dedicated Quick Access keys on the lightweight handset. The menu setting of the IPLEX RX and RT is simplified for easy and quick operation. |

User‐friendly Menu Icons

The IPLEX RX intuitive menu shows the options for image overlay | All menus of the IPLEX RX and RT are displayed with easy‐to‐understand icons. An inspector can intuitively recognize the menus and efficiently operate the desired feature or setting. |

Rugged and Durable for Reliable Performance Even in Harsh Environments

Robust Body

|

The IPLEX RX and RT pass the impact tests including vibration and drop from a height of 1.2 m/ 3.9 ft.

The tough system compliant with Military Standards withstands rough treatment and ensures reliable operation in difficult environments. |

Operable in All Weather

|

The IPLEX RX and RT comply with internationally recognized Military Standards (MIL‐STD‐810F and MIL-STD‐461F)* as well as IP55, passing a range of severe environmental tests, such as blowing rain/dust, high humidity, and icing rain. In addition, the daylight view monitor featuring low-reflection displays clear images even under bright sunlight.

*Reference specification page for MIL-STD compliance details |

High‐durability Insertion Tube

Special processed tungsten braid |

Operators are often required to inspect objects inside narrow paths with rough or sharp surfaces. The insertion tube of the IPLEX RX and RT has a crush and abrasion-proof design and is covered with a tough, special processed tungsten braid.

In addition, the IPLEX RX insertion tube features high temperature resistant up to 100 °C/ 212 °F. A high temperature sensor beeps and display visual warning to prevent overheating. |

Advanced Functionality to Provide Inspection Resuit and Work Efficiency

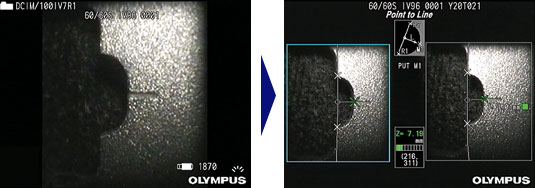

Stereo Measurement for Reliable Inspection*

Our Stereo Measurement technology offers defect measurements from various angles with simple operations. The newly implemented screen switching function allows easy detection of defects with large, single screen and a quick shift to measurement.

* Optional function for IPLEX RX (Except 20m type)

Under observation Stereo Measurement mode (Measuring the distance of a defect) |

InHelp™ Inspection Assist Software

|

InHelp, the inspection data management and reporting software, streamlines many aspects of remote visual inspections with the IPLEX RX and RT. The software greatly improves work efficiency and simplifies inspections by organizing stored images on the IPLEX RX and RT, generating detailed inspection reports on a PC with simple click operation.

*Confirmed with Toshiba FlashAir Wireless LAN SD card |

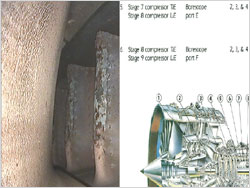

Instruction Manual Display

Comparison display between an inspected image and PDF document | IPLEX RX has a function to display PDF document. Instead of alternately facing printed inspection manuals and inspected images, you can see both of them on the IPLEX RX monitor at once. This unique capability improves your inspection speed and efficiency. |

Specifications

| SCOPE VARIATION | ||||||||

| IPLEX RX Model No. | IV9420RX | IV9435RX | IV9620RX | IV9635RX | IV9650RX | IV9675RX | 4549001 IV96100RX*1 | IV98200RX*1 |

| IPLEX RT Model No. | IV9420RT | IV9435RT | IV9620RT | IV9635RT | IV9650RT | IV9675RT | 4549023 IV96100RT*1 | IV98200RT*1 |

| Scope diameter | φ4.0 mm (0.157 in.) | φ6.0 mm (0.236 in) | φ8.5 mm (0.334 in) | |||||

| Scope length | 2.0 m (6.6 ft) | 3.5 m (11.5 ft) | 2.0 m (6.6 ft) | 3.5 m (11.5 ft) | 5.0 m (16.4 ft) | 7.5 m (24.6 ft) | 10.0 m (32.8 ft) | 20.0 m (65.6 ft) |

| Exterior | High durability tungsten braid | |||||||

| Tube flexibility | Uniformed stiffness | Tough Tapered Flex™ tube with flexibility gradually increasing toward the distal end. | ||||||

|

Articulation angle

UP/DOWN/RIGHT/LEFT | 130° | 130° | 150° | 130° | 120° | 100° | *2 | *3 |

|

Approx. System weight

(with battery) | 2.9 kg (6.4 lb) | 3.0 kg (6.6 lb) | 3.1 kg (6.8 lb) | 3.2 kg (7.1 lb) | 3.3 kg (7.3 lb) | 3.5 kg (7.7 lb) | 3.7 kg (8.1 lb) | 5.2 kg (11.44 lb) |

| IPLEX RX | IPLEX RT | |

| INSERTION TUBE | ||

| Articulation mechanics | Improved TrueFeel™ scope tip articulation with electronic power-assisted, manual articulation | |

| Temperature sensor | 2-stage indicator for high temperature warning. | N/A |

| Illumination | Ultra-high intensity LED illumination | |

| Optical tip adaptor locking mechanism | Double Threaded Attachment, with O-ring seal | |

| HANDHELD CONTROL UNIT | ||

| Dimensions (W x D x H) | 365 x 93 x 192 mm (14.4 x 3.7 x 7.6 in.) | |

| Weight | Approx. 1.0 kg | |

| Quick access button: | The following features have dedicated quick access buttons, levers or joysticks on the hand control unit: Scope articulation control, Image controls, Record still/video, Menu access | |

| MAIN UNIT | ||

| Dimensions (W x D x H) |

227 x 64 x 189 mm (8.9 in. x 2.5 in. x 7.4 in.)

Maximum Demensions: 239 x 99 x 215 mm (9.4 in. x 3.9 in. x 8.5 in.) | |

| LCD monitor | 6.5 in. daylight-view LCD, anti-reflective type | |

| Power supply |

Battery: 10.8 V nominal, approx. 120-minute operating time.

AC power: 100 V to 240 V, 50/60 Hz (with supplied AC adaptor) | |

| Video output standard | VGA | |

| USB connector | Type A connector, Version 2.0 standards | |

| SOFTWARE MANIPULATIONS | ||

| Image manipulations | 5X digital zoom, 10 step digital brightness control | |

| Gain control | 3 step adjustable gain control with exclusive WiDER™ brightness level balancing technology. | N/A |

| Sharpness control | 4 step adjustable sharpness control | N/A |

| Saturation control | 3 step adjustable control of color saturation | N/A |

| Display text options | 30-character title display | |

| RECORDING MANAGEMENT FUNCTIONS | ||

| Recording media | USB flash memory (1GB standard, compatible with recommended USB flash device) | |

| Overlay | Selectable 30 character title with date, time and system setting | |

| Thumbnail image display | Recorded images can be displayed as thumbnails | |

| Still image recording | Resolution -- H768 x V576 (Pixel) | |

| Recording Format -- Compressed JPEG format | ||

| Size of a Single Image -- Approx. 300 KB (Approx. 3,400 images per 1 GB memory) | ||

| Video recording | Resolution -- H640 x V480 (Pixel) | |

| Recording Format -- AVI MPEG-4 format, Can be played on the Windows Media Player. | ||

| Size of a Single Image -- Approx. 500 KB per second (Approx. 30 min. per 1 GB memory) | ||

| STEREO MEASUREMENT FUNCTIONS — Optional function for IPLEX RX* | ||

| Distance | Distance between two points. | |

| Point-to-Line | Perpendicular distance between a point and a user-defined line. | |

| Depth | Orthogoral depth/height distance between a point and a user-defined plane. | |

| Area/Lines | Multiple point circumstance and area measurement. | |

*Stereo Measurement functions are available by upgrading the IPLEX RX except IV98200RX.

| OPERATING ENVIRONMENT | ||

| Operating Temperature | Insertion Tube |

In air: –25 º to 100 ºC (–13 º to 212 ºF) IPLEX RX

–25 º to 80 ºC (–13 º to 176 ºF) IPLEX RT |

| In water: 10 º to 30 ºC (50 º to 86 ºF) | ||

| Other parts than above |

In air: –10 °C to 40 ºC (14 ºF to 104 ºF) with battery

0 ºC to 40 ºC (32 ºF to 104 ºF) with AC power adaptor | |

| Relative Humidity | All parts | 15 to 90 % |

| Liquid Resistance | All parts | Operable when exposed to machine oil, light oil or 5 % saline solution. |

| Waterproofing | Insertion Tube |

Water pressure resistance:

IV94 series -- Up to an equivalent to 3.5 m (11.5 ft) in depth IV96 series -- Up to an equivalent to 7.5 m (24.6 ft) in depth IV98 series -- Up to an equivalent to 20.0 m (65.6 ft) in depth |

| Other parts than above |

Operable in blowing rain conditions (Battery compartment must be closed).

Not operable underwater. | |

| MIL-STD COMPLIANCE | |

|

The operating environment performance is confirmed by the following MIL-STD-810G and MIL-STD-461F (excluding IV96100RX and IV96100RT).

No warranty is given as to damage-free under any conditions. Please ask Olympus sales representative for details. | |

| Type | Method |

| Vibration | MIL-STD-810G, Method 514.6, Procedure I (General vibration test) |

| Shock | MIL-STD-810G, Method 516.6, Procedure IV (Transit drop test) |

| Water Resistance | MIL-STD-810G Method 506.5, Procedure I (Rain and Blowing rain test) |

| Humidity | MIL-STD-810G, Method 507.5 |

| Salt Fog | MIL-STD-810G, Method 509.5 |

| Sand and Dust | MIL-STD-810G, Method 510.5, Procedure I (Blowing dust test) |

| Icing/Freezing Rain | MIL-STD-810G, Method 521.3 |

| Electromagnetic Interference (EMI)*4 | MIL-STD-461F, RS103, (Radiated susceptibility test for non-metallic above deck shipboard conditions) |

| Explosive Atmosphere | MIL-STD-810G, Method 511.5, Procedure I (Operation in an explosive atmosphere test) |

*1. Built-to-order

*2. 60 degree as reference value

*3. 70 degree as reference value

*4. Excluding IV9650RX/ IV9650RT/ IV9675RX and IV9675RT

| Tip Adapter Optical Specifications | ||||||||||||

| OPTICAL TIP ADAPTOR VARIATION | ||||||||||||

| 6.0 mm Viewing Tip Adaptors | ||||||||||||

| AT40D-

IV96 | AT80D/

NF-IV96 | AT80D/

FF-IV96 | AT120D/

NF-IV96 | AT120D/

FF-IV96 | AT220D-

IV76 *4 *5 *6 | AT80S-

IV96 | AT120S/

NF-IV96 | AT120S/

FF-IV96 | AT100D/

100S-IV76 *5 | |||

| Optical system | Field of view | 40 º | 80 º | 120 º | 220 ° | 80 º | 120 º | 100 º | ||||

| Direction of view | Forward | Side | Forward/Side | |||||||||

| Depth of field*1 | 200 to ∞ mm | 9 to ∞ mm | 35 to ∞ mm | 2 to 200 mm | 19 to ∞ mm | 3 ~ 100 mm *7 | 15 to ∞ mm | 1 to 25 mm | 3 to ∞ mm | 15 ~ ∞ mm | ||

| Distal end | Outer diameter*2 | ø6.0 mm | ø8.4 mm | ø6.0 mm | ||||||||

| Distal end*3 | 18.4 mm | 18.9 mm | 18.8 mm | 18.9 mm | 18.8 mm | 21.1 mm | 24.2 mm | 27.1 mm | ||||

| 4.0 mm Viewing Tip Adaptors | Oil Clearing Tip | Stereo Tip Adaptors (4.0 mm and 6.0 mm) | ||||||||||

| AT80D/FF-IV94 | AT120D/

NF-IV94 | AT120D/

FF-IV94 | AT100S/

NF-IV94 | AT100S/

FF-IV94 |

AT120D/

NF-IV94R-W | AT50D/

50D-IV94 | AT50S/

50S-IV94 | AT60D/

60D-IV96 | AT60S/

60S-IV96 | |||

| Optical system | Field of view | 80 º | 120 º | 100 º | 120 º | 50 º/50 º | 60 º/60 º | |||||

| Direction of view | Forward | Side | Forward |

Forward/

Forward | Side/Side |

Forward/

Forward | Side/Side | |||||

| Depth of field*1 | 35 to ∞ mm | 2 to 200 mm | 17 to ∞ mm | 2 to 15 mm | 8 to ∞ mm | 2 ~ 200 mm | 5 to ∞ mm | 4 to ∞ mm | 5 to ∞ mm | 4 to ∞ mm | ||

| Distal end | Outer diameter*2 | ø4.0 m | ø4.0 mm | ø6.0 mm | ||||||||

| Distal end*3 | 19.0 mm | 21.7 mm | 19.0 mm | 24.3 mm | 28.4 mm | 24.9 mm | 31.3 mm | |||||

| 8.5 mm Viewing Tip Adaptors | ||||||||||||

| AT120D/FF-IV98 | AT80D/FF-IV88 | AT120D/NF-IV88 | AT120S/NF-IV88 | AT120S/FF-IV88 | ||||||||

| Optical system | Field of view | 120 º | 80 º | 120 º | ||||||||

| Direction of view | Forward | Side | ||||||||||

| Depth of field*1 | 25 to ∞ mm | 35 to ∞ mm | 35 to ∞ mm | 1 to 25 mm | 5 to ∞ mm | |||||||

| Distal end | Outer diameter*2 | ø8.5 mm | ||||||||||

| Distal end length*3 | 19.0 mm | 22.9 mm | 22.9 mm | 29.5 mm | 29.5 mm | |||||||

*1. Indicates the viewing distance with optimal focus.

*2. The adaptor can be inserted into a ø4.0 mm, ø6.0 mm and ø8.5 mm hole when it is mounted on the scope.

*3. Indicates the length of the rigid portion at the scope's distal end when mounted.

*4. This adapter has a lens protruding. Please handle with care so as not to scratch the lens by force insertion.

*5. These adapters do not support scaler measurement.

*6. This adapter has protrusions for lens protection. Therefore, protrusions may appear in the vertical direction of the screen, however it is not a malfunction.

*7. This adapter is suitable for pipe inspection up to φ50 mm diameter.

Accessories

Video Transmitter

VT200-RGB (Manufacturer:Scalar Corporation)

| Optional Wireless LAN enables users to share live video, capture images, and record video using an iPad digital device. *Sales area of this product is limited to Japan, United States, Canada, China and Europe . |

Oil Clearing Tip Adapter (Built to order)

| AT120D/NF-IV94 based optical tip adapter designed to sustain clear visibility under inspection environment where oil adheres frequently. An ideal solution for Wind Power gearbox inspection. |

Optical Tip Adaptor

| The wide range of the IPLEX RX and RT tip adaptors meets the optical requirements of any application. |

Lithium-ion Battery

| NC2040NO29 |

Rigid Sleeve Sets

| MAJ-1253 (for 6.0 mm insertion tube) |

Guide Tube for 6.0 mm diameter Long Scope*

*Built-to-order | (For 5.0 m or 7.5 m long insertion tube) |

AC Power Adaptor

| The IPLEX RX and RT can be operated with either the provided AC power adaptor or the battery. |

Application Photo Gallery

Please click on the image or movie to get the larger view.

|  |  |

|  |  |

|  |  |

IPLEX RX Turbine blade

IPLEX RX Compressor blade

IPLEX RX Combustion Chamber

Have a question about a product or solution featured in this video?

Demonstration of Stereo Measurement

What is Stereo Measurement?

Stereo measurement tip adapters have two lenses like human eyes, which allow accurate measurements in three dimensions at any angle.

IPLEX Stereo MeasurementNarration Language:English

.jpg?rev=68DD)

IPLEX Stereo Measurement : Distance ModeNarration Language:English

.jpg?rev=DF90)

IPLEX Stereo Measurement : Point-to-line ModeNarration Language:English

.jpg?rev=455F)

IPLEX Stereo Measurement : Depth ModeNarration Language:English

IPLEX Stereo Measurement : Area/Lines ModeNarration Language:English

Have a question about a product or solution featured in this video?