Welcome to Olympus’ ASNT Fall Conference 2020 Virtual Showcase

We wish we could be in Orlando to catch up with everyone!

Olympus continues to support inspectors of today and tomorrow, providing our expertise and technology to advance the knowledge and capabilities of the nondestructive industry.

Attend our in-booth demonstrations on some of our latest offerings

How NOT to Use TFM

Speaker: Emilie Peloquin

Time: Nov 10 at 12:40 – 12:55 pm EST

Advanced Inspection Solutions Using High-Frequency, High-Sensitivity Arrays

Speaker: Curtis Dickinson

Time: Nov 11 at 12:40 – 12:55 pm EST

Easy and Efficient Long Seam Weld Inspection

Speaker: Brandon Reitz

Time: Nov 12 at 12:40 – 12:55 pm EST

Five minutes before the webinar starts, a “LIVE” button will appear next to the “CHAT” button. Click it, and you will be in the presentation. All presentations are free of charge and no registration required!

Schedule a one-to-one video call with any of our experts!

We can also provide in-depth virtual demos on most of our portable instruments.

Curtis Dickinson

Title: Senior Application Engineer, Nondestructive Testing

Expertise: Phased Array

Schedule A MeetingBrandon Reitz

Title: Senior Application Engineer, Nondestructive Testing

Expertise: PAUT, TFM, Scanners

Schedule A MeetingDianne Hillhouse

Title: Senior Marketing Manager, Oil & Gas / Chemical / Inspection

Expertise: XRF and Videoscopes

Schedule A MeetingJames Bittner

Title: Applications Engineer; Technology Specialist, NDT

Expertise: Military and Eddy Current

Schedule A MeetingDusty Moore

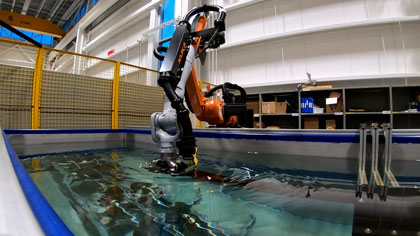

Title: Senior Marketing Manager, Systems Integrations

Expertise: Systems Integration

Schedule A MeetingEmilie Peloquin

Title: Director of Global Advanced Product Support, NDT

Expertise: PAUT, TFM

Schedule A MeetingDaly Souissi

Title: Director of Global Markets, NDT

Expertise: PAUT, TFM, Complex Geo

Schedule A MeetingStephan Couture

Title: Global Product Application Leader, NDT

Expertise: PAUT, TFM, OmniScan

Schedule A MeetingGhislain Morais

Title: Global Product Application Leader, NDT

Expertise: Eddy Current, ECA, Bond Testing

Schedule A MeetingUnable to find a time that fits for you or want schedule a separate meeting outside of ASNT?

Contact UsChoose a Technology to Learn More

Olympus Around the World

Our global team of experts made quick tutorial videos to help you get the most out of your OmniScan™ X3 phased array flaw detector.

Watch NowEnter Our Raffle for a Free Customized OmniScan X3 Jacket

Visit this page daily* and enter our raffle for up to three chances to win a custom OmniScan™ X3 jacket.

Winners will be contacted immediately after the event to arrange the delivery.

*There is a maximum of three entries per person. Offer Limited to ASNT Attendees in the United States and Canada.View Olympus’ ASNT presentations and topics below.

Speaker

Presentation Time

Topic

Abstract

Nov 11 at 11:30 am and 12:30 pm EST

Leading Through Change

Few change initiatives succeed in today’s complex global environments. For the best chance... of success, leaders need to be able to gauge and respond to others’ resistance and inspire their team members to take ownership of change. I have been through so much change in our industry and organization and will discuss success drivers that I have learned along the way.

Nov 11 at 11:30 am EST

Solving HTHA Single-Sided Access Inspection with a Dual Linear Probe

HTHA (High Temperature Hydrogen Attack) damage mechanisms have been heavily... under the microscope in recent years. Many new inspection techniques, as well as older, more familiar techniques, are being used in conjunction to detect this intergranular damage. This paper offers a new approach to HTHA inspection when access to the component is physically limited to only one side of the weld. This challenging scenario is common in the field as components are often welded to a flange or fitting that prevents using an ultrasonic probe on both sides of the weld. This new inspection strategy allows for more energy to penetrate the component as well as reduced surface noise. It was found to be overall less noisy than other methods, like TFM and PAUT.

Nov 11 at 12 pm EST

How to Set Your Industry 4.0 Digital Journey into Motion

NDT organizations worldwide are realizing the significance of Industry 4.0 and the value of... investing in digital platforms, but many companies are finding it difficult to know where and how to start. Join this session to learn how to embark on your digital journey. We will discuss how to kickstart this process, which involves the critical first step of assessing your current work processes to determine major paint points. Maybe it’s the collection and management of NDT data? Maybe it’s report generation or resource management? Taking a close look at these pain points enables you to gather valuable insights and determine where digital tools may be most helpful. Ultimately, there are infinite possibilities of what can be done with digital tools, but targeting solutions too broadly can result in paying for more than is necessary and struggling to adopt. We will share client case studies to provide context on how this process benefits your organization’s digital adoption. In closing, we will discuss how to prioritize and find solutions that will improve your workflows, saving your company time and money.

Nov 11 at 3 pm EST

Improving Phased Array Beam Divergence in Small-Diameter Pipe Weld Insepction

Ultrasonic phased array inspection of smalldiameter pipe welds present many... different challenges. One such challenge is the divergence of the phased array beam that occurs upon entering the pipe surface and from reflecting off the ID surface. This divergence caused by the size of the transducer elements can cause a loss in sensitivity as well as errors in measuring the length of indications detected. Through the use of a novel wedge design, this presentation aims to show the concepts and means by which the quality and consistency of your small-diameter weld inspections can be improved.

Nov 11 at 3:30 pm EST

Portable X-Ray Fluorescence for In-Field Testing of Mercury (Hg) Contamination in Petrochemical Process Piping

Quickly and accurately detecting mercury contamination in process piping is a fundamental need for... the petrochemical industry. Virtually all petroleum contains some amount of mercury compounds. The mercury present in the crude oil can amalgamate with the steel in the process piping, storage tanks, and marine vessels. This mercury accumulation poses additional challenges during decommissioning, so it is essential that the mercury contamination is identified, quantified, and properly disposed of. Portable X-ray fluorescence (XRF) provides a fast and accurate means of quantifying mercury contamination in piping, with microgram per square centimeter (µg/cm2) detection. In a matter of seconds, portable XRF can quantify the degree of mercury intercalation into the surface of the steel piping. Using portable XRF on-site prior to demolition enables asset owners to make informed decisions during decommissioning and helps prevent contaminated material from entering the recycling stream. In this paper, we present quantitative results that substantiate the performance of portable XRF for detecting mercury contamination in piping. Recommended testing protocols are discussed as well common concerns about interferences in testing methods. Additional advances in instrument connectivity allow real-time result sharing, even between remote locations.