Routine corrosion monitoring in pipelines just got easier. We now offer Pipecheck™ Analyze software from Creaform®, a solution that provides advanced tools for corrosion monitoring. Using phased array data from an OmniScan® flaw detector, the software enables you to gain an accurate, realistic evaluation of your pipeline’s integrity.

1. Get More Data

More data can lead to greater confidence in your pipeline assessment. Having the true wall thickness data from your flaw detector is good, but the information Pipecheck Analyze software provides is even better. The software’s powerful tools for corrosion monitoring provide strength, the river bottom path, the maximum allowable operating pressure, the worst-case profile, and remaining life calculations.

2. Automatic Burst Pressure Calculations

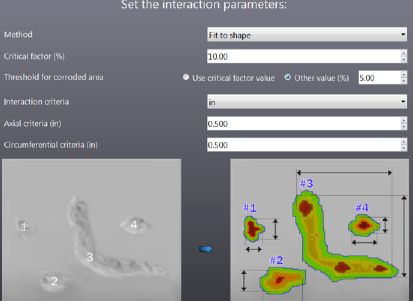

Now, you don’t have to spend time making complex burst pressure calculations. The software provides code compliant burst pressure calculations (ASME B31G, Modified B31G, and Effective Area methods), enabling engineers to predict when a pipe needs to be repaired or replaced to increase safety and minimize unplanned downtime.

3. See the Whole Picture

Map both the inside and outside of your pipes. If you already have a Creaform laser scanner to map a pipe’s outside surface, you can add ultrasonic testing technology and use the software you already have to map the inside of the pipe, providing you with a comprehensive look at both the OD and ID.

4. Easier Reporting

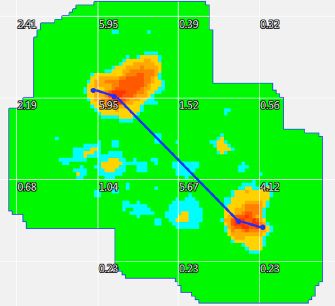

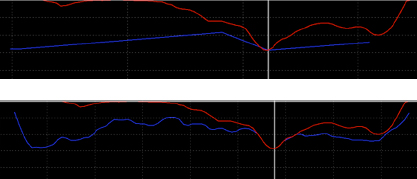

When the job’s done, the software helps you generate reports quickly and with data that’s easy to understand. Pipecheck Analyze software makes it simple to stitch your scans together, enabling you to see potential corrosion locations over a larger area and facilitating faster reporting. The software also offers 3D visualizations of the pipe and indications as well as 2D color mapping with river bottom path overlay, helping you highlight areas of interest. The 2D profile section (in both the axial and circumferential directions) makes it simple to visually communicate what’s happening in the pipe.

5. Save Time with Templates

Export your OmniScan data as

Related Content

Using Eddy Current Array to Detect Corrosion Pitting in Stainless Steel Tubing

Corrosion Gaging with Dual Element Transducers

Olympus Corrosion Inspection Solutions

Get In Touch