As inspeções no mercado de asas giratórias muitas vezes envolvem turbinas menores, que normalmente exigem um videoscópio de 4 mm de diâmetro para realizar avaliações minuciosas. Nossos sistemas de videoboroscópio IPLEX™, com uma seleção versátil de adaptadores de ponta óptica de 4 mm de diâmetro, incluindo as objetivas de medição, há muito tempo são as soluções ideais para inspeções detalhadas nesse campo.

No entanto, até mesmo o sistema de 4 mm pode apresentar desafios em certas aplicações. Acessar áreas de acesso mais difícil pode ser complicado e navegar por espaços estreitos pode levar ao desgaste prematuro da malha de proteção e da extremidade distal do tubo de inserção. Além de aumentar os custos de manutenção, esse desgaste também pode comprometer a qualidade a precisão das inspeções ao longo do tempo.

Apresentando o IPLEX TX II ultrafino: Projetado para precisão e durabilidade

O videoboroscópio IPLEX TX II oferece uma solução inovadora com seu diâmetro fino de 2,2 mm e uma ponta distal rígida mais curta, fornecendo fácil acesso a áreas que antes eram desafiadoras. Seja ao inspecionar lâminas de turbinas axiais pequenas, ao navegar por câmaras de combustão de raio pequeno ou ao acessar os espaços intrincados de compressores centrífugos, o IPLEX TX II permite que os inspetores visualizem essas áreas com alta clareza.

O videoboroscópio IPLEX TX II está disponível com uma sonda rígida de 1,8 mm ou com uma sonda flexível de 2,2 mm de diâmetro, que permite que você obtenha um campo de visão amplo em espaços com pontos de acesso muito pequenos.

O diâmetro menor e o design aprimorado do IPLEX TX II permitem uma navegação mais fácil, minimizando o desgaste e proporcionando uma qualidade de imagem excepcional, um recurso essencial para tomar decisões precisas e informadas sobre a integridade dos ativos.

Reduza os danos à sonda em áreas com acesso estreito de turbinas de motores turboeixo e turboélice

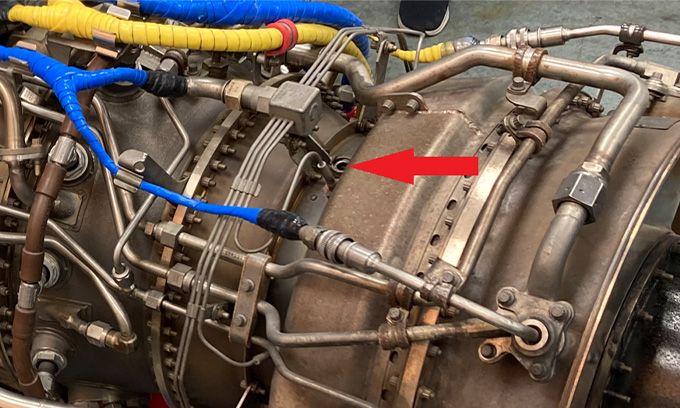

Durante as avaliações de RVI de rotina de motores turboeixo e turboélice pequenos, as turbinas do gerador de gás, as pás guia e as turbinas de potência de primeiro estágio são áreas frequentemente inspecionadas. Os pontos de acesso dessas áreas (veja as imagens abaixo) oferecem um acesso muito restrito para um tubo de inserção de 4 mm. Ao ser inserido nesses pontos de acesso, um tubo de 4 mm normalmente sofre desgastes e danos consideráveis na malha da seção de dobra, no adaptador de ponta e no sistema de articulação.

Exemplo de um ponto de acesso (seta vermelha) às turbinas do gerador de gás, às pás guia e às turbinas de potência de primeiro estágio de um motor turboeixo ou turboélice pequeno.

É aqui que o tubo de inserção de 2,2 mm do IPLEX TX II é útil! Com sua ponta distal rígida mais curta de 7,8 mm, a sonda fina desliza facilmente nas portas de inspeção, fornecendo acesso a todas as áreas importantes dos estágios da turbina e das pás guia.

Inspetor navegando a sonda flexível do videoboroscópio TX II pelo ponto de acesso estreito de uma turbina pequena.

É possível ver as seções da turbina em detalhes vívidos, girando a turbina para examinar cada borda de ataque e de fuga das lâminas. O campo de visão amplo, a iluminação brilhante e a reprodução fiel de cores permite que os inspetores obtenham uma compreensão detalhada da integridade interna da turbina.

|

|

|

O campo de visão amplo do IPLEX TX II permite visualizar várias lâminas ao mesmo tempo e, posicionando o tubo de inserção entre as pás guia, você pode girar a turbina para inspecionar cada lâmina.

Para quantificar totalmente a extensão de qualquer dano encontrado, você pode precisar testar com uma sonda de 4 mm que ofereça medição estéreo. No entanto, é possível usar o videoboroscópio de 2 mm IPLEX TX II para a maioria das suas inspeções de geradores a gás e seções de turbina de potência, reduzindo muito o desgaste do seu sistema de 4 mm.

Libere novos recursos de inspeção com o videoboroscópio IPLEX TX II

Com sua capacidade de alcançar e inspecionar claramente até os espaços mais restritos, o IPLEX TX II oferece um avanço significativo para as pessoas que trabalham em ambientes de inspeção exigentes. Essa ferramenta capacita os inspetores a acessar áreas críticas com facilidade, garantindo avaliações confiáveis e otimizando a manutenção geral dos ativos.

Para experimentar o IPLEX TX II em primeira mão e explorar como ele pode transformar o seu processo de inspeção, entre em contato com o seu representante local da Evident para agendar uma demonstração grátis.

Conteúdo relacionado

Melhor formação de imagens em espaços pequenos com o videoscópio IPLEX™ TX II

Técnicas de inspeção de guias de ondas com um videoboroscópio ultrafino

Apoio à prontidão à missão de aeronaves militares com videoscópios adequados ao serviço