- Home

- Microscope Measurement and Inspection Solutions for Electric Vehicle Development and Manufacturing

- Analytical Solutions for Metal Content in Battery Manufacturing

Elemental Analysis of Metal Content in Battery Manufacturing

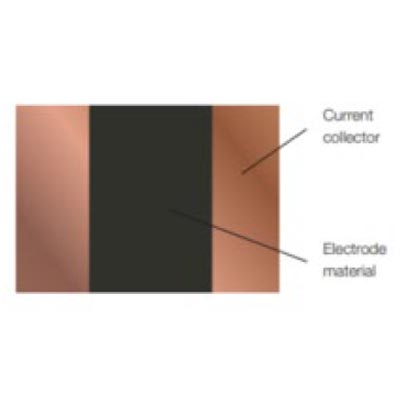

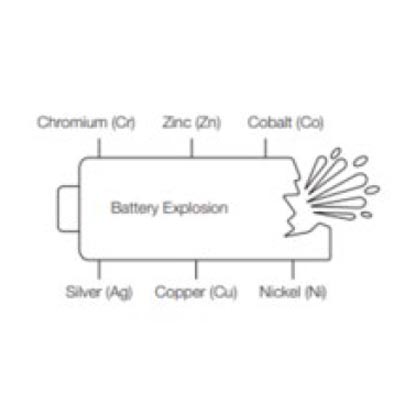

Compliance requirements set certain limits on the concentration of metal elements (e.g., iron, silver, cobalt, zinc, copper, nickel, and chromium) in lithium battery electrode materials. These limits are typically 30–50 ppm, as even a very small amountof foreign metals in lithium battery materials can cause a short circuit when the battery is in use. Short circuits can lead to a battery explosion, so it is critical to check for foreign metals accidentally introduced during the battery manufacturing process.

Our Solution

Our Vanta™ handheld XRF analyzer performs nondestructive elemental analysis of battery metals at ppm levels in seconds. It can easily distinguish different types of metallic materials and their source within manufacturing. This includes the metallic foreign substances (e.g., iron, nickel, copper, cobalt, and aluminum) used to adhere separators and electrode substrates in battery manufacturing.

Vanta analyzers can be used throughout the battery supply chain to prevent loss of materials, incorporate quality control into the manufacturing process, and provide material data, including coating thickness, material type, and elemental concentration.

Our optional Vanta Work Station enables closed beam testing in an interlocked chamber for added safety and ease of use. The Work Station runs on AC or battery power for indoor and outdoor use. Handling powders and liquids is simple with an optional sample cup. With handheld XRF, it is possible to measure powder and film regardless of the size of the object being measured.

Vanta Handheld XRF Analyzer |  |  |

Application Notes

Explore related applications:

|

|