Image of microscopic bumps on an integrated chip.

Measuring the Height of Microscopic Bumps for Flip Chip Bonding

Mounting integrated circuit (IC) chips on a printed circuit board (PCB) using a grid of microbump solders is a technique called flip chip bonding. To ensure a proper connection between the IC and PCB, the height of the bumps must be uniform. For this reason, the bump height must be measured quickly and accurately during production.

Olympus' Solution: Height Measurement Using the OLS5000 Industrial Microscope

The LEXT OLS5000 3D laser scanning microscope can provide precise and fast height measurement at the microscopic level thanks to a range of innovative features:

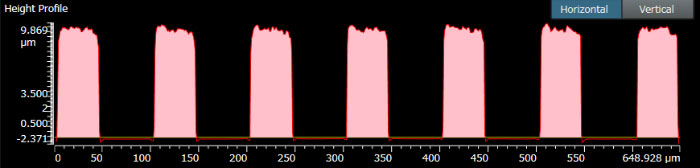

(1) With the microscope’s unique PEAK algorithm, it takes only about 10 seconds to acquire data in a 649 µm × 640 µm area of bumps 20 µm high.

(2) The system has a multiple-area data acquisition function, which enables you to specify multiple areas and obtain the data of those areas simultaneously.

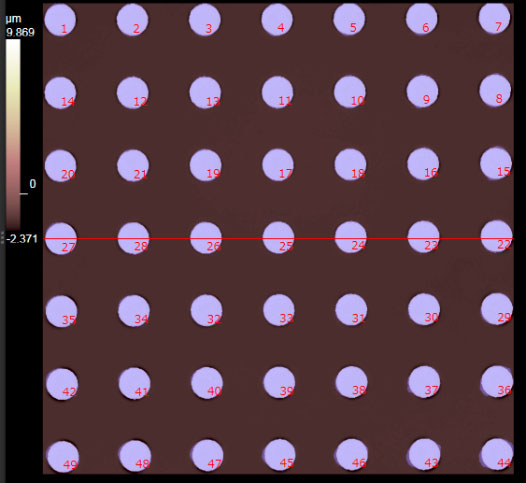

(3) By setting the height reference plane for the image to be acquired, you can measure the heights of all the bumps within the field of view at one time.

Setting the reference plane for height measurement.

All the bump heights within the field of view can be automatically measured.

(4) All the details and steps of an operation you have performed can be stored as a template when producing a report. When repeating a measurement, you can reload the template to obtain a report analyzed using the same procedure parameters.

(5) Typical bump measuring systems inspect bumps at high speed, but they do not work well for very fine microscopic bumps. The OLS5000 microscope helps ensure accuracy and reproducibility suitable for the height measurement of microscopic bumps.