Vanta handheld XRF analyzers enable you to analyze a range of coated materials in the warehouse or scrap yard quickly and nondestructively.

Benefits include:

Continuous operation at high temperatures: Up to 50 °C (122 °F)

Continuous operation at high temperatures: Up to 50 °C (122 °F)

IP55/IP54 rated: Withstands dirt, dust, and rain to protect against hazards in challenging environments

IP55/IP54 rated: Withstands dirt, dust, and rain to protect against hazards in challenging environments

Drop tested (MIL-STD-810G): Protects against falls and reduces the need for costly repairs

Drop tested (MIL-STD-810G): Protects against falls and reduces the need for costly repairs

Cloud-technology enabled: Access and share data across multiple platforms from any location

Cloud-technology enabled: Access and share data across multiple platforms from any location

In the scrap recycling industry, knowing the type and quality of scrap metals, as well as separating the wanted and valuable materials from unwanted scrap, is important for profitability. With the increase in nickel (Ni), zinc (Zn), and aluminum (AI) commodity prices, it is all the more vital to determine the elemental composition in scrap metals to determine the right selling price.

Fast Alloy Identification Using Handheld XRF

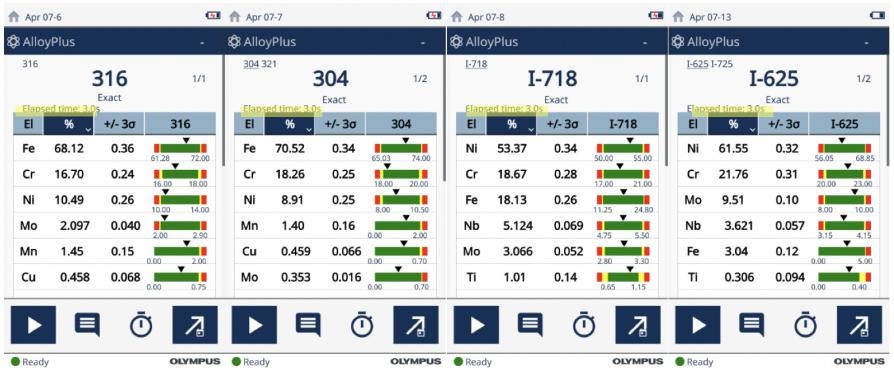

Vanta handheld XRF analyzers identify alloy grades fast. Figures 1–4 below show how the Vanta analyzer can differentiate types of stainless steel and Inconel alloys in seconds.

Vanta analysis results (from left to right): Figure 1: Stainless Steel 316, Figure 2: Stainless Steel 304, Figure 3: Inconel 718, Figure 4: Inconel 625

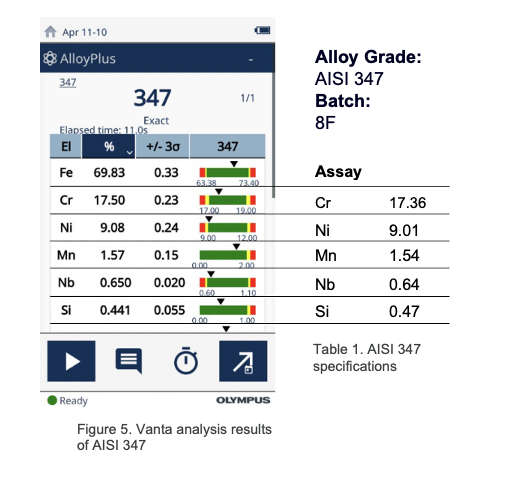

The Vanta analyzer also provides accurate elemental concentration for more stringent requirements. Figures 5 shows Vanta analysis results of AISI 347. For comparison, Tables 1 shows the assay values of the certified reference materials (CRMs) of AISI 347.

With an intuitive user interface and customizable software, the Vanta XRF analyzer is easy to use with minimal training. The rugged device provides accurate results fast, boosting productivity and throughput no matter the environment or working conditions.