In the intricate world of metal fabrication, quality control and material verification are critical. Mill test reports (MTRs) play an important role in these processes. As businesses strive for top-notch quality assurance and adherence to specifications, understanding the nuances of mill test reports becomes important.

This comprehensive guide delves into the core aspects of mill test reports, answering key questions about their content, certification, and broader implications for businesses, including how to “trust but verify” MTRs.

Operators verify metal parts to confirm they meet industry standards and specifications.

In the dynamic landscape of steel fabrication, the demand for reliable information on mill test reports is on the rise. As businesses navigate the complexities of ensuring the quality of materials used in their processes, the role of MTRs emerges as a linchpin for success.

What Is a Mill Test Report (MTR)?

A mill test report is a document that verifies a material’s physical and chemical properties. In the metals industry, mill test reports can go by a variety of names: MTRs, materials test report, metallurgical test report, or manufacturer’s test report.

Regardless of which term is used, MTRs play an important role in quality control as they show that the metal product complies with international standards. Some MTRs are considered certified—a certified material test report or “mill cert” for short. These are analogous to Certificates of Analysis (CoA) in other industries.

The Importance of Mill Test Reports in Metal Fabrication

Mill test reports are not just pieces of paper. They are the foundation of quality assurance in steel fabrication. Confirming that the alloy received meets specifications and quality standards is crucial for businesses aiming for product excellence.

MTRs show up throughout the metal manufacturing supply chain, such as for raw materials, billets and bars, steel products of all types (plates, pipes, etc.), and machined metal products. Inspection at each stage in the manufacturing chain is critical to help ensure that no material mix-up has occurred. Many manufacturers require an inspection certificate from their vendor but will subsequently perform their own material inspection.

What Information Is Included in a Mill Test Report?

A mill test report is a treasure trove of data. From chemical composition to mechanical properties like yield strength, a detailed breakdown is provided. The material grade, often a critical factor, is meticulously documented for transparency in the supply chain. The material composition of the metal part must be verified by chemical analysis to confirm it meets specifications. This is critical to prevent material mix-ups, where the wrong component or material can lead to accelerated corrosion or mechanical failure.

How Do You Confirm the Alloy You Receive Meets Your Specifications and Quality Standards?

Quality assurance starts with clear specifications. Setting stringent standards and implementing robust quality control measures are imperative. Mill test reports play a pivotal role in the verification process, offering a snapshot of the material's journey from raw material to final product. Beyond the MTR, it is often necessary to have a secondary verification of a material’s composition. A fast and nondestructive way to do this is with X-ray fluorescence.

An operator verifies material composition using a Vanta™ handheld X-ray fluorescence (XRF) analyzer.

Verifying Mill Test Reports from Vendors: The Role of X-Ray Fluorescence

In the pursuit of quality within the supply chain, businesses often explore advanced techniques for verifying mill test reports. X-ray fluorescence, or XRF, is a powerful method that enables nondestructive analysis of material composition. This technology enables manufacturers to validate the information provided in MTRs, confirming the accuracy of chemical composition without compromising the integrity of the material.

Material verification with XRF is fast, typically only 2–3 seconds. This is quicker than other chemical composition measurements. It also has the added advantage of being completely nondestructive, so no valuable product is lost. This positive material verification can be done manually or automatically, including in-line during production.

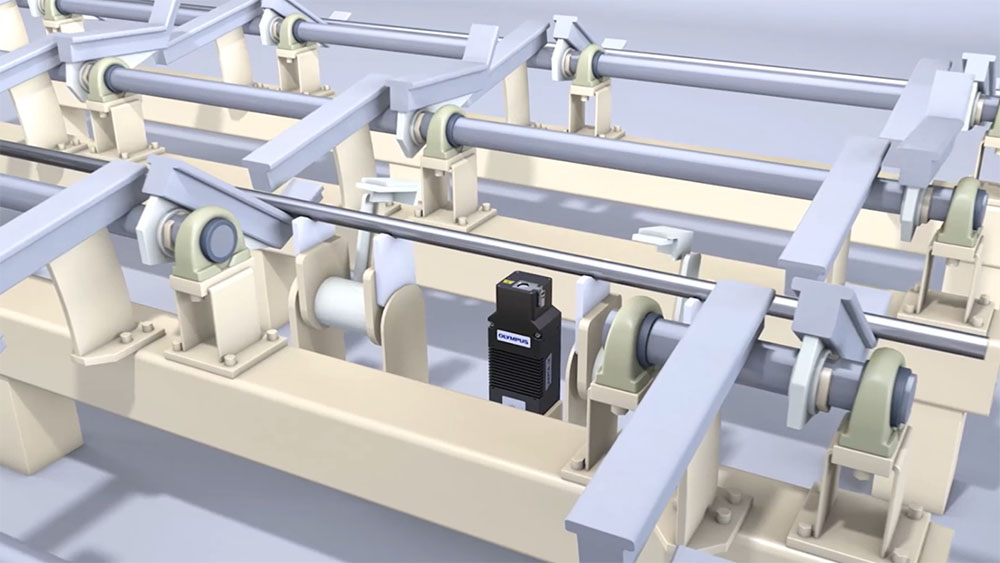

Automated material verification of metal rods using an integrated Vanta iX in-line XRF analyzer.

XRF is particularly valuable when dealing with vendors and raw material suppliers. By employing this technique, businesses can independently verify the elemental composition of the received materials. This additional layer of inspection enhances the overall quality control process, providing a robust way to cross-verify critical information from mill test reports.

Certified Mill Test Reports for Added Quality Assurance

A certified mill test report adds an extra layer of assurance. But what makes an MTR certified? Third-party certification agencies play a vital role in verifying the accuracy of the provided information by offering objectivity in the quality assessment. Some MTRs are issued by the manufacturer from their own internal testing.

Who Can Issue the Mill Test Report?

Not all entities are authorized to issue mill test reports. Understanding the legitimacy of the issuer is crucial. Accredited bodies with the necessary qualifications should be entrusted with this responsibility to maintain the integrity of the certification process.

What Is the Purpose of a Mill Test Certificate?

Beyond a mere document, a mill test certificate serves the purposes of traceability and accountability. It confirms compliance with industry standards and regulations, contributing to the overall quality management in steel fabrication.

How to Review Certified Mill Test Reports in Manufacturing

Reviewing a mill test report is not a perfunctory task. It requires attention to detail. A step-by-step guide can aid in the process, helping manufacturers identify discrepancies and ensure continuous improvement in their manufacturing processes.

Operators verify the material composition of a metal part for quality assurance and compliance.

Key Takeaways about Mill Test Reports in Metal Manufacturing

Mill test reports are indispensable tools for quality assurance and compliance in steel fabrication. Carefully examining MTRs, understanding their certification process, and leveraging them for risk reduction are key steps toward achieving excellence in the competitive landscape of steel fabrication and metal manufacturing. The integration of advanced technologies like X-ray fluorescence further strengthens the foundation of trust in the steel fabrication process.

To learn more about incorporating manual or automated XRF into your metal manufacturing QA/QC process, contact our team for expert assistance.

Related Content

Smarter Manufacturing with Award-Winning In-Line XRF Analysis

9 Reasons to Automate Material Analysis with the Vanta™ iX In-Line XRF Analyzer