A Fast, Safe Alternative for Weld Inspections

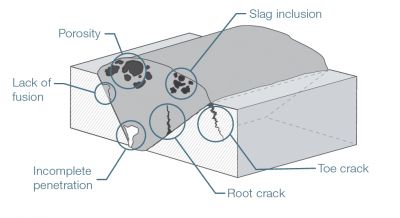

Reliable detection of weld defects is a challenge in many industries that use welding on a large scale, such as the oil and gas and petrochemical industry. Dissimilar weld materials and stainless steel welds are even more difficult to inspect. Lack-of-fusion defects in particular are sometimes hard to detect.

The current gold standard in nondestructive testing of welds is radiography. However, there are safety concerns about the harmful X-rays used in radiography – as well as limitations to its use in inspection. With the right setup, ultrasonic inspection can address these limitations, as it uses soundwaves rather than ionizing radiation to detect defects quickly, reliably, safely and without interruption of work.

Radiographic Inspection

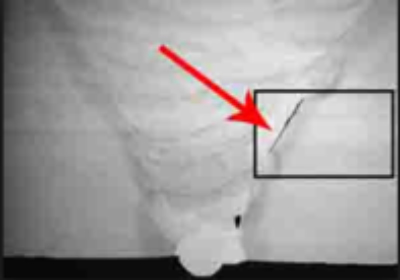

Radiography as the current gold standard relies on high-energy photons traveling through metal towards a detector on the other side. Any irregularities inside the component – either in the weld, the parent material or at the interface – show up as brighter or darker regions on the detector. The main limitation of the use of radiography is the harmful effect of the radiation used. Due to the many risks to human health caused by high-energy X-rays, safeguards are needed to avoid exposure to radiation. This usually means that a large area in the direct vicinity of the inspection has to be evacuated, disrupting the work in the area of inspection. Probability of detection is likely to be a factor when choosing a method for weld inspections. There is evidence1 that the contrast of defects such as lack of fusion can be low when using radiography. This means that the probability of detection of these defects in stainless steel or dissimilar-material welds is reduced. |  Figure 2: Lack of Fusion |

Another key drawback of radiographic inspection is the time it takes to inspect a component. In some cases, long exposures lead to increased inspection times and therefore lengthy disruptions to work in the area. When long X-ray exposure times are required, switching to faster methods can lead to cost savings in different ways: time spent by the inspector and minimal disruption.

Ultrasonic Inspection of Stainless Steel or Dissimilar- Material Welds

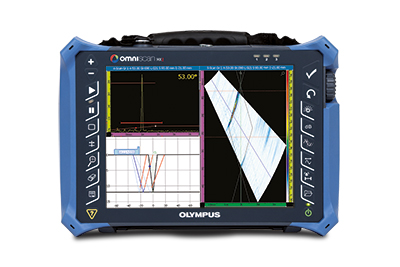

An alternative technique for inspecting welds in search of defects is ultrasonic inspection. Ultrasonic flaw detectors, such as Olympus’ OmniScan MX2 (figure 3) use sound waves rather than radiation to inspect components. Detection is based on the deflection of these sound waves at interfaces within the component. To maximize probability of detection – and to enable imaging and sectorial scans – ultrasonic phased array probes can be used. What is Phased Array? |  Figure 3: Olympus OmniScan MX2 |

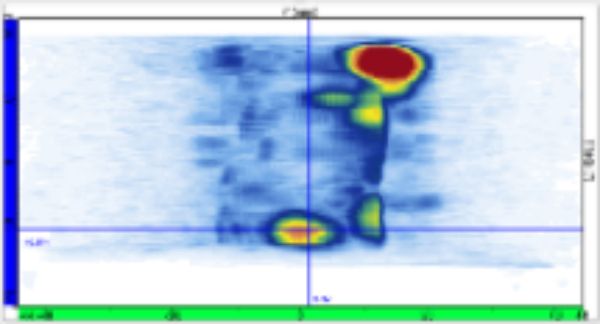

Pitch–catch inspection can be carried out using either conventional, single-element probes or using phased array probes where each transducer contains multiple elements; these probes are known as dual matrix array (DMA) probes (figure 5). In phased array inspections a flaw detector controls each element individually.

Among the benefits of phased array are imaging capabilities, sectorial scans and easy coverage of a weld without moving the probe back and forth. These capabilities, combined with better control over the ultrasonic beam, simplify inspection for improved probability of detection.

Figure 4: Olympus’ Handheld Vanta XRF Analyzer

Noise levels can be reduced by using separate emitting and receiving probes.

Figure 5: Dual Matrix Array Probe

A DMA probe containing two transducers with 28 elements each combines the benefits of phased array inspection with those of the pitch–catch technique.

Summary

Ultrasound inspection offers important benefits over radiography, particularly with difficult types of weld materials; it does not require ionizing radiation, thereby improving safety and avoiding work interruptions. It can also make inspection faster and offer higher probability of detection of certain hard-to-see defects. These benefits make ultrasonic inspection equipment, such as Olympus’ OmniScan MX2 phased array flaw detector, highly suitable for large-scale weld inspections that have to be done quickly, safely and with a high probability of detection.

More information can be found in the comprehensive white paper at www.olympus-ims.com/en/easy-ultrasonic-phased-array-inspection-ofcorrosion- resistant-alloys-and-dissimilar-weld-materials/. This white paper gives advice on the different parameters to consider for setting up ultrasonic inspection correctly for the best possible inspection results.

1 UK Health and Safety Executive report (www.hse.gov.uk/research/rrpdf/rr301.pdf)

Author

Thierry Couturier

Senior Product and Applications Specialist – Ultrasound and Phased Array

Scientific Solutions Division

OLYMPUS EUROPA SE CO. KG