Overview

Simple, Controlled Engine Turbine RotationTurbine engines—including aeroengines, power generation turbines, and marine engines—all require remote visual inspection (RVI) using borescopes to help ensure that they’re working properly. In many cases, hundreds of blades need to be thoroughly inspected as quickly as possible to minimize downtime. Enerpac’s Sweeney Digital Turning Tool (DTT) enables you to control the turbine’s blade rotation during borescope inspection using a convenient, palm-sized remote control or hands-free foot pedal. When used with an IPLEX series videoscope, a single inspector can thoroughly inspect an engine turbine efficiently. *This product is not available in some areas. Consult your local Evident representative for more information. |  |

Reduce Your Labor CostsThe Sweeney Digital Turning Tool enables a single operator to control the engine rotation while conducting the inspection. Reduced Risk of Borescope or Engine DamageSince one person is controlling the inspection and engine rotation, the tool eliminates miscommunications if one person is inspecting and the other is controlling the rotation as well as the physical burden of using a wrench in a hard-to-reach location to manually rotate the blades. The DTT’s torque overload sensor shuts down the tool if excessive torque occurs, helping prevent damage to the engine and borescope. Features that Ease Your InspectionThe Sweeney Digital Turning Tool has features that help make your inspections more efficient.

|

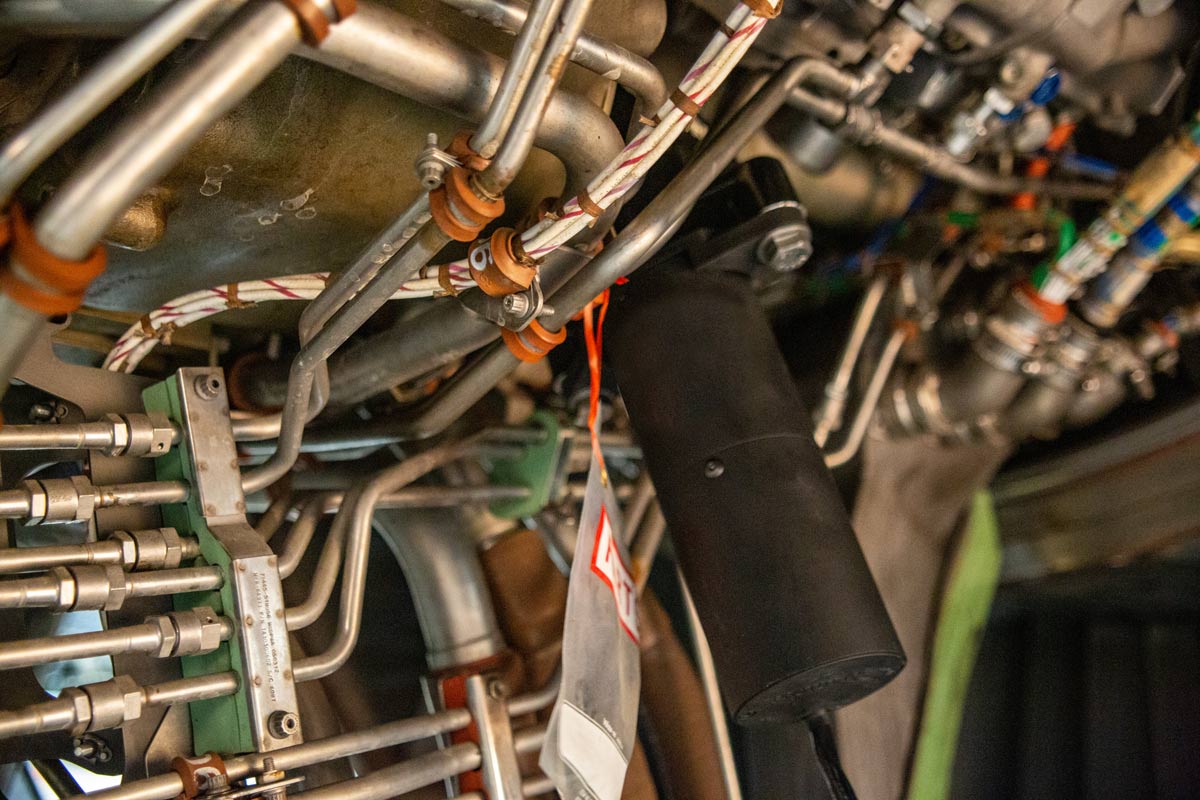

Attach the Sweeney Digital Turning Tool to the engine access port, and its drive motor enables you to turn the turbine blades. |

Recommended Borescope/Videoscope SystemsIPLEX videoscopes are proven RVI solutions for aviation, power generation, and marine gas turbine borescope inspections and are used all over the world. When paired with Enerpac’s Sweeney Digital Turning Tool, you can make your turbine inspections faster, safer, and more efficient.

|

Specifications

Supported Engines

|

Specifications

|