多年来我们注意到,客户并不是使用统一的正确或标准的方式管理测厚仪上的数据。不同行业的检测人员采用的数据管理方式各不相同:通过无线方式将所有厚度读数传输回平板电脑上的资产管理程序,通过USB手动导出A扫描,或只是简单地以手写方式记录结果。

在测厚仪上使用无线连接的好处

随着39DL PLUS(39DLP)超声测厚仪的发布,我们推出了更多连接仪器的方式,与此同时,仍然支持并改进原有的久经考验的方法。内置的Wi-Fi和蓝牙功能*有助于实现包括远程监测或将波形数据推送到平板电脑的新型工作流程。

对于那些正在考虑在测厚仪上采用无线连接技术或持观望态度的用户,请了解将无线连接纳入工作流程中的诸多好处:

- 减少人为错误:手动创建报告可能会导致用户在需要将信息从一个设备或程序重新输入到另一个设备或程序时出现打字错误。虽然使用音标和三方沟通等人为因素工具可以减少这些错误,但并不总是能得到一致的应用。

- 节省时间:减少手动输入不仅可以减少错误,还可以节省时间,尤其是在使用报告生成器的情况下。

- 无需寻找电缆:我们都有过这样的经历;在工作现场到处寻找电缆,这不仅浪费了大家的时间,而且还令人沮丧!

- 更好地保存记录:信息容易丢失;将数据推送到外部源,就增加了另一个除了设备本身的存储位置。

39DLP测厚仪的所有无线连接方式

那么,如何在实践中使用无线功能来节省时间、减少错误、更好地记录并简化工作流程呢? 下面简要介绍一下39DLP超声测厚仪可以通过无线方式进行哪些操作,以提高厚度检测效率:

1. 内置Wi-Fi功能

有了Wi-Fi连接功能,39DLP的用户现在就可以访问以下高级功能了:

- 与第三方应用程序和软件通信

- 单次发送厚度数据和波形

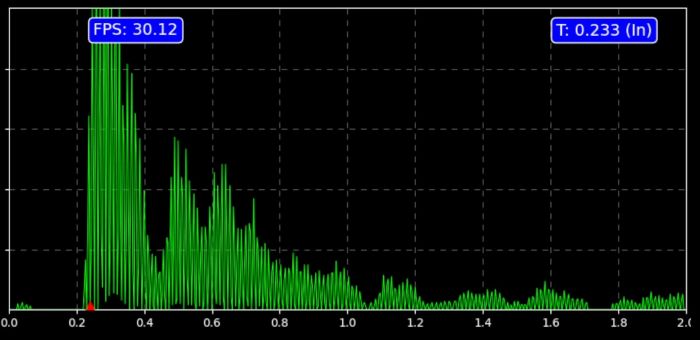

- 以最高30 Hz的频率将实时波形串流传输至另一台设备

通过Wi-Fi将波形串流传输到PC机上。

39DLP测厚仪提供了与第三方应用程序接口集成的功能,大大扩展了远程控制能力。其中包括单次发送,即将波形数据包发送到一个程序,以使用用户配置的信息。值得注意的是,用户现在可以高达30 Hz的频率实时串流传输波形,提供可持续监控或记录的实时数据。这些信息可集成到无人机、检测软件、资产管理程序或基于平板电脑的应用程序。

想象一下这样的场景:某家工厂在爬墙无人机上安装了一个39DLP测厚仪,用于监控无法通过脚手架进入的储罐。检测数据可实时串流传输到电脑,其内置报警阈值可在壁厚低于公差时提醒操作人员。在遥控无人机上安装39DLP测厚仪进行远程监测,实现了无需危险攀爬即可对难以到达的区域进行评估,而且还减少了准备时间。

2. 内置蓝牙功能

39DLP超声测厚仪的蓝牙功能应用广泛,包括以下功能:

- 与Evident iOS Link Plus应用程序 通信

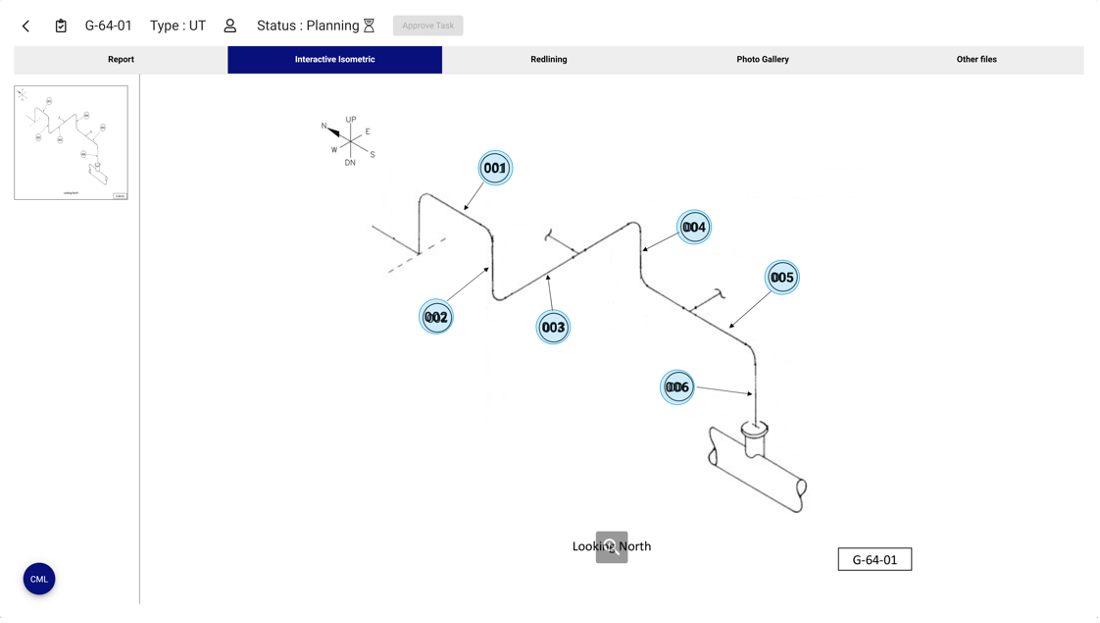

- 通过Inspection Project Manager (IPM)(检测项目管理器)应用程序,将厚度直接输入到等距管道图中

- 与Link-Wedge软件连接,可将厚度读数直接发送到大多数基于 Windows的程序中

iOS上的Link-Wedge软件。

从只需按下39DLP测厚仪上的按钮即可将读数发送到平板电脑,到与我们的Evident Connect应用程序(如Inspection Project Manager)相连接,所有这些有用的功能都可以改善您的工作流程。Link Plus应用程序可与iOS设备配合使用,收集数据并将数据以CSV、TXT或FTP格式导出或附加到电子邮件或短信中。IPM应用程序提供了一种在等距图上查看检测点并创建详细报告的方法。

在IPM应用程序(iOS)的等距图上查看检测点。

39DLP测厚仪的全部有线数据传输功能

使用更高级功能的客户可能会问,为什么从39DLP测厚仪传输文件时不使用无线连接呢? 原因有很多,这里仅列举几个:

- 某些行业对Wi-Fi和蓝牙有严格的规定,如政府、军事或核能行业

- 某些区域的检测需要两人参与(如只能借助绳索攀爬进入的区域):一个人进行检测,另一个人记录结果

- 某些国家对设备的无线使用有严格规定

- 公司政策

对于那些更愿意以有线方式传输数据或受限于某个特定程序或方法的用户,我们提供手动连接选项,以支持他们的工作方式。

以下是39DLP超声测厚仪的所有有线连接选项:

使用microSD存储卡传输数据

- 将CSV文件中的数据导出至microSD卡中

- 导出调查文件中的数据,并传输至GageView PC软件中

通过USB或RS-232端口以有线方式传输至PC机中

- 直接将CSV文件导出至您的电脑中

- 直接将调查文件导出至GageView软件

- 与前代机型相比,数据传输速度提高了4到5倍

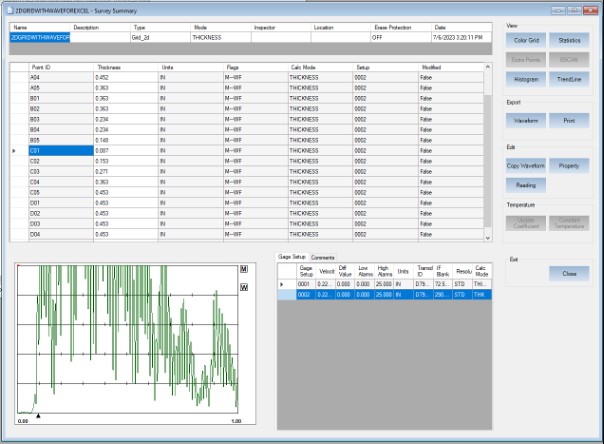

GageView PC软件

- 通过USB双向传输厚度读数

- 创建自定义注释文件,并将其附加到调查文件中

- 生成或打印以颜色编码的栅格报告以及统计数据

- 查看A扫描和读数

GageView软件是一款基于Windows的应用程序,可以收集、创建、打印和管理来自39DL PLUS测厚仪的数据。

无线和有线连接选项的总结

许多行业和领域的检测人员都依赖于39DLP超声测厚仪,因此对仪器的使用会有很多方法。借助内置无线功能,检测人员有更多机会改变工作流程,提高检测效率,甚至可以前所未有的方式使用39DLP测厚仪!

如果您想进一步了解39DLP测厚仪及其连接选项,请联系我们,我们将为您提供现场或虚拟演示。

*Wi-Fi和蓝牙在某些地区尚待认证。 请联系您当地的Evident代表,了解有关产品供应的详细信息。

蓝牙(Bluetooth )文字符号和徽标为Bluetooth SIG, Inc.公司所拥有的注册商标,Evident公司对这些符号的使用已经获得授权。