激光显微镜解决方案

►Feature of a laser microscope

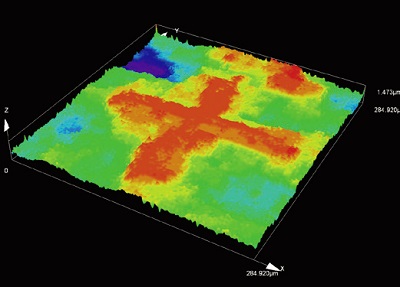

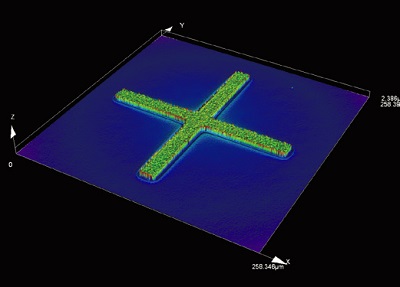

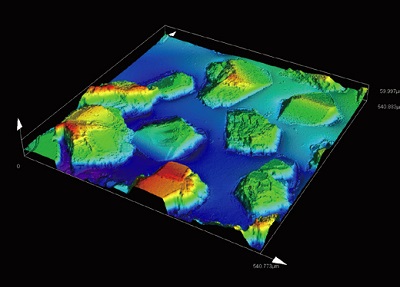

1. Sub-micron 3D observation/ measurement

| Observe steps in the nanometer range and measure height differences at the sub-micron level. |

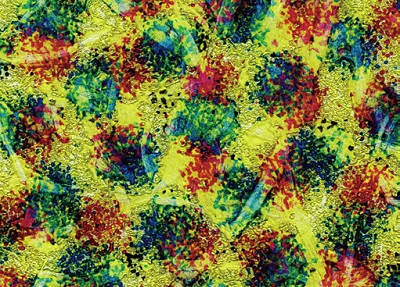

2. ISO25178-compliant surface roughness measurement

| Measure surface roughness from linear to planar. |

3. Non-contact, nondestructive, and fast

| No sample preparation required—simply place the sample on the stage and you're ready to measure. |

►Advantages of a laser microscope

Conventional measuring tools | Laser microscope | |

Optical microscope, digital microscope | ||

•Unable to measure small shapes •Poor lateral resolution •Non-traceable measurement results |

| •Precision 3D measurement •0.12 μm lateral resolution •Traceable measurement results |

Stylus surface roughness tester | ||

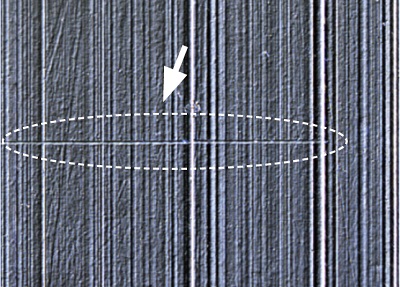

•Can damage the sample’s surface •Information from only one line •Difficult to place the stylus on a target position |

| •Non-contact measurement doesn’t damage the sample •Acquire information from an entire plane •Pinpoint measurement |

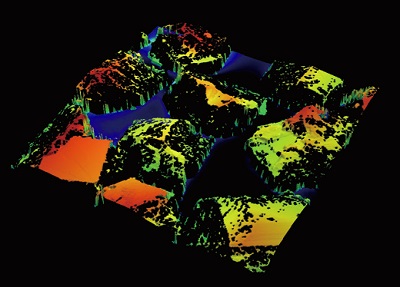

White light interferometer | ||

•Has difficulty capturing rough surface shapes •Poor lateral resolution makes positioning difficult •Inconvenient inclination adjustment |

| •Accurate rough surface measurement by capturing small slopes •0.12 μm lateral resolution •Just place your sample on the stage to start measurement |

Scanning electron microscope (SEM) | ||

•No color information •Samples must be destroyed and prepared in advance •3D shape measurement is not possible |

| •High-definition color observation •Nondestructive and no sample preparation required •Precise 3D measurement |