Welcome to Olympus IMS library - Join us for prerecorded and live webinars to discuss trending topics. Missed a webinar? No problem, you can listen again. Don’t see a topic you’d like to discuss? Use our feedback form or contact our experts directly for help.

Upcoming Webinars | On-Demand Webinars | Experts

Basics of X-ray Fluorescence (XRF) for Positive Material Identification (PMI)

X-ray fluorescence (XRF) has extensive applications in the inspection services market. It is fundamental for positive material identification (PMI) for in-the-field and plant maintenance. This talk explores the basics of XRF theory, and the application of XRF for positive material identification (PMI) and weld inspection. Special attention is given to relevant applications of this technology in the oil and gas (O&G) sector. Testing methods, sample considerations, and strategies and tools for data management are discussed.

Olympus Tube Inspection Solutions—A Demonstration of Our Probe and System Advantages

Olympus HTHA-Optimized Probes and Techniques

Early detection of high-temperature hydrogen attack (HTHA) damage can help oil, gas, and petrochemical facilities avoid catastrophic failures of critical high-pressure assets. While it is essential to evaluate the equipment’s condition, HTHA is challenging to detect and assess, including for ultrasonic testing (UT). For this reason, Olympus created probes specifically designed to detect HTHA-induced damage at an earlier stage. The solution comprises Dual Linear Array™ (DLA) probes that are used to perform the pitch-catch technique and phased array (PA) probes that are fine-tuned for the total focusing method (TFM). These methods, combined with TOFD screening, are used as part of a complete multitechnology inspection strategy.

Olympus ECA Solutions Demo

Join our eddy current testing (ECT) expert for this demo of an eddy current array (ECA) inspection using the MagnaFORM™ weld inspection scanner. Learn how ECA can improve and speed up conventional eddy current inspections. Discover the types of ECA probes Olympus offers and how our solutions can help you save costs and reduce the turnaround time of weld inspections.

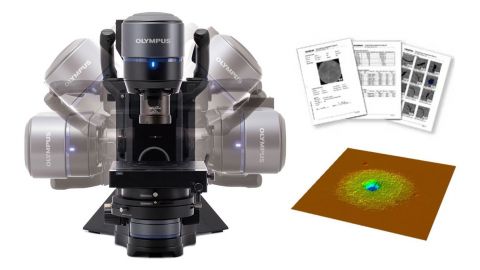

OLYMPUS Stream™ Software—A New Standard for Microscope Digital Imaging Workflow Flexibility

With the integration of digital cameras and software into microscope systems, microscopy analysis using conventional industrial microscopes has become easier and simpler. Digital microscope systems now offer digital solutions for acquisition, measurement, storage, and reporting as well as advanced solutions for materials analysis, such as particle classification, grain sizing, cast iron analysis, and much more.

In this webinar, you will learn how to streamline your daily conventional microscopy workflow using OLYMPUS Stream™ software-based digital solutions.

Automated ERW Process-Control Inspection Using PA and Conventional UT Technology

Inspecting weld integrity during ERW pipe manufacturing is an industry requirement. Traditional inspection systems use operator-controlled weld alignment to ensure the correct position of the ultrasonic testing (UT) probe. As material quality and performance standards continuously evolve, so do the inspection requirements. Our solution for process-control of ERW pipes stands out because it automatically positions the conventional UT probes for the inspection using a patented weld tracking algorithm and a phased array (PA) probe. The result is a fully automated, easy-to-use ERW inspection system that helps ensure the quality of ERW welded pipes by inspecting the weld for flaws while simultaneously monitoring the scarfing profile.

Smart Workflows with Advanced Laser Scanning Microscope Measurements and Experiments

Fluorescence Microscopy and Its Applications in Industry

Automotive Car Catalyst Recycling with Vanta Handheld XRF

Making a Better Design of Experiment with the Smart Experiment Manager